- Home

- en

- biomedical

- als-smartfreezer

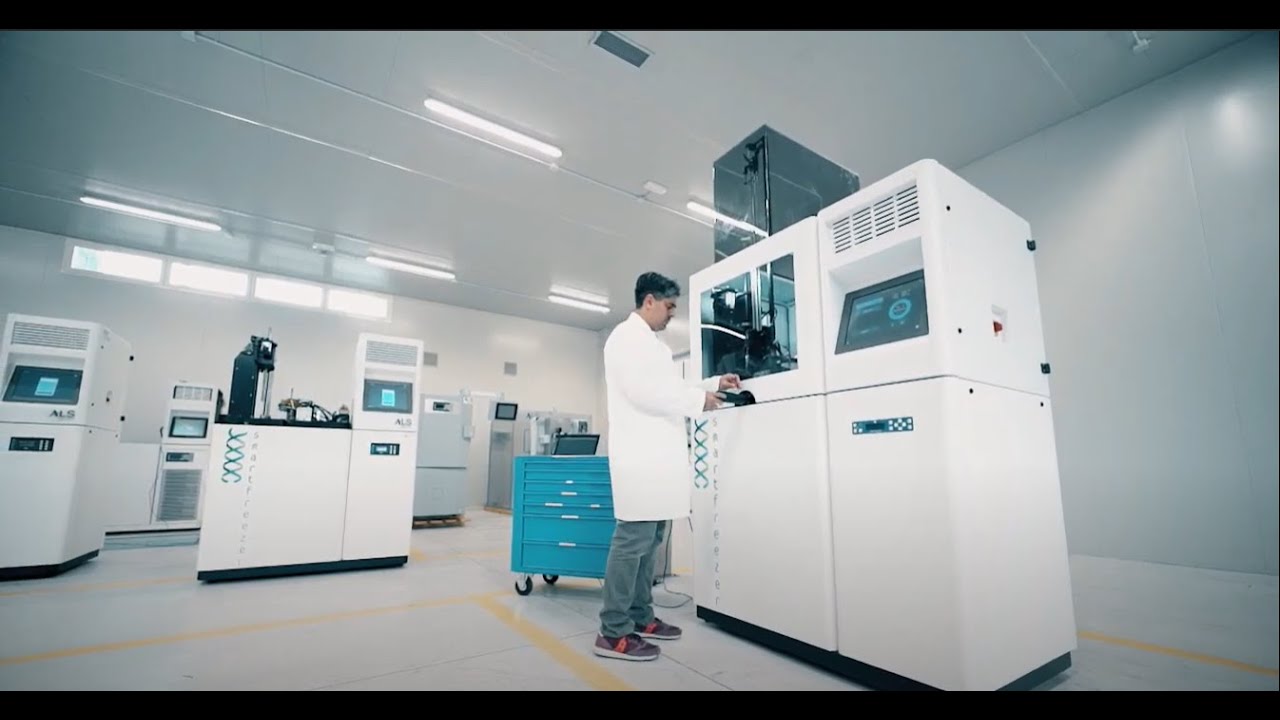

Angelantoni SMARTFREEZER® EVO and EVO LAB series

Biological samples are valuable as long as they are clearly identifiable and reliably stored. Prevent damage due to incorrect handling and preserve the value of your biorepository: With our robotic solution for automated storage and retrieval of ampoules with biological material, at cryogenic temperatures(-180°C).

Traditional cryogenic storage systems expose samples and users to great risks. They are labor-intensive, time-consuming and error-prone. Users must wear protective equipment to avoid health hazards. Manual handling carries the risk of mix-ups and physical damage to the biological material.

Our Smartfreezer prevents incorrect handling and offers maximum safety for both the user and the samples.

- +

What we mean by cryopreservation

Cryopreservation is a set of methods that allow medium and long-term preservation of biological material (cells, tissues, biological fluids, etc.) at low temperatures in order to prepare them for future diagnostic, clinical or research purposes (temperatures between -80 and -196 °C).

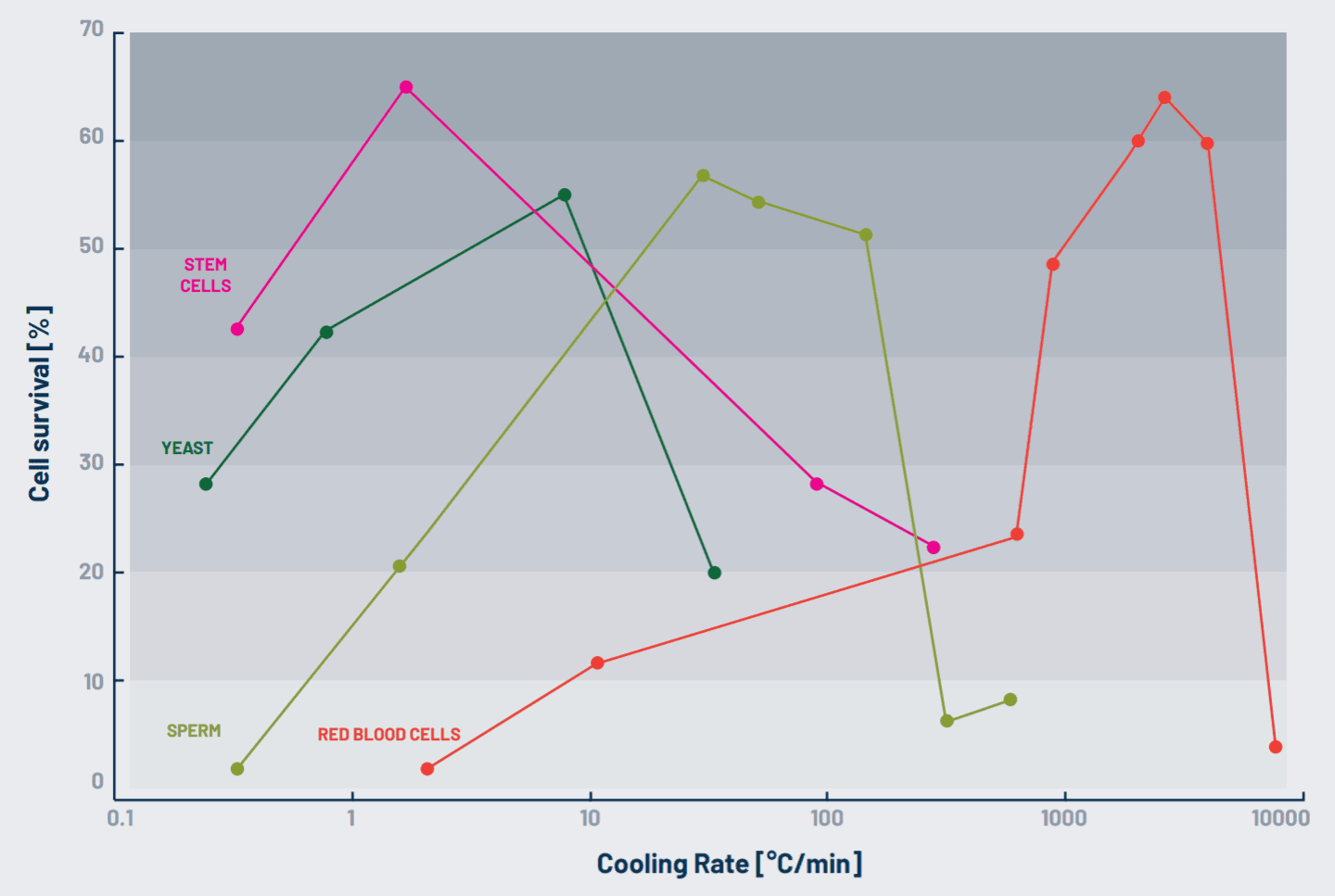

The aim here is to preserve the qualities and functionality of the cryopreserved biological material as faithfully as possible, so that they correspond to their original state before the cryopreservation/hypothermia process. Different cell types react differently to different freezing/thawing protocols. The nucleation of ice, which is strictly dependent on the radius of curvature of the biological particle, must be avoided at all costs. It is clear that the smaller the core, the lower the nucleation temperature. When freezing biological material, the latter must be regarded as a suspension; in fact, both the intracellular and extracellular environment remain in an aqueous state due to supercooling.

Each cell type has an optimal "window" for the survival cooling rate, which is narrow at temperatures close to 0 °C, but increases with decreasing temperature.

The cooling rate that optimizes the freeze/thaw response of each cellular system (controlled freeze-cooling) can be established as the fastest cooling rate in a given device without the formation of intermolecular ice damaging the system. Biological matter is in fact described as soft matter (viscoelastic) in which cooperative forces act, i.e. there is a correlation between viscosity variation, deformation rate and temperature variation (fluid dynamic system).

State-of-the-art sample management

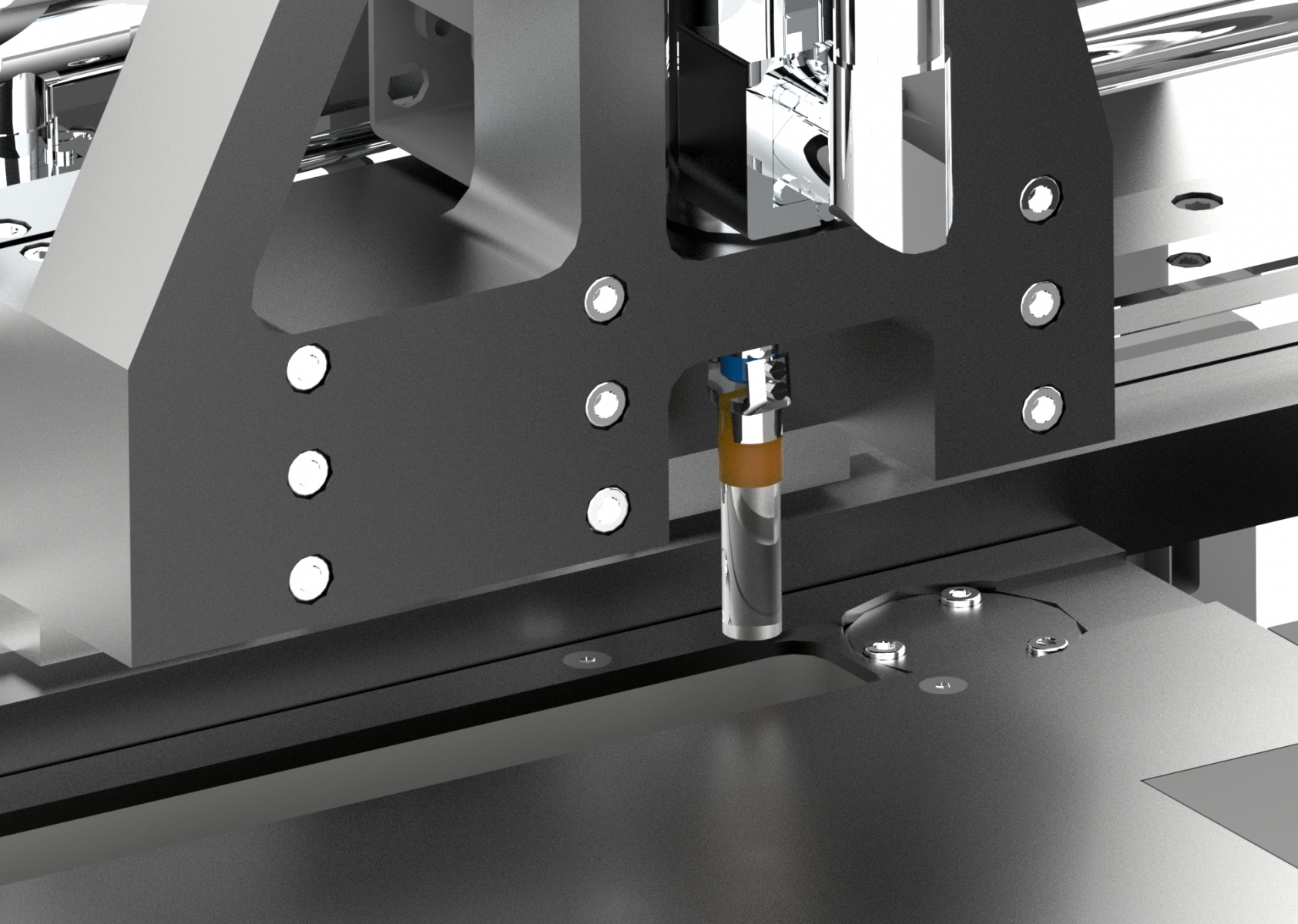

Loading and unloading is done individually per ampoule, which prevents samples stored in the device from being exposed to unnecessary thermal stress. Employees do not have to come into contact with a cold surface or liquid nitrogen while using the device. All they have to do is select the desired sample via the controller. Using a compressed air-driven gripper, the robot controls the transport of the samples from the room temperature to the low temperature environment inside the device. Here, 10 perforated disks are stacked, into which the ampoule to be stored is inserted.

All information about user actions, storage conditions and sample history can be easily exchanged with an external laboratory information management system (LIMS).

A revolution in storage systems

Conventional cryogenic temperature storage systems are manually operated and expose samples and operators to various risks. Indeed, the user must wear protective equipment to prevent possible suffocation and/or frostbite. With this type of operation, users are also responsible for selecting the correct samples, a process that involves handling heavy racks in uncomfortable tanks. When taking individual samples, all samples stored in the rack are exposed to heating. All these events are avoided thanks to the automated Smartfreezer action.

Selective selection

Samples are stored in nitrogen gas, which not only provides the safest conditions, but also prevents the risk of cross-contamination between samples. The guaranteed temperature range is -180°C to -150°C. The device is also equipped with an internal barcode reader for sample identification and a touchscreen PC for easy and intuitive user operation.

Access to the system requires a user name and password. All actions performed by the user are recorded in a LOG file, which makes it possible to determine the exact sequence of all activities at any time. The number of different access levels is freely selectable. Access rights can be configured individually by the administrator, whereby different users can be granted or revoked authorizations for the execution of each individual process.

The advantages of our Angelantoni Smartfreezer

Fully automated system

Automation completely eliminates human error and ensures maximum traceability.

- +

Show more

Angelantoni Life Science has developed the only fully automated solution in the cryogenics market that eliminates the risks and complications associated with the storage and retrieval of samples stored at cryogenic temperatures. Manual handling is not only prone to errors when loading and unloading samples, but can also be responsible for exposing samples to temperatures that are detrimental to their usability.

Safety for the operating personnel

The user is never exposed to cryogenic temperatures with direct contact to liquid nitrogen.

- +

Show more

Conventional cryogenic temperature storage systems are operated manually and expose samples and operators to various risks.

Indeed, the user must wear protective equipment to prevent possible suffocation and/or frostbite. With this type of operation, users are also responsible for selecting the correct samples. A process that involves handling heavy racks in uncomfortable tanks. When taking individual samples, all samples stored in the rack are exposed to heating.

All these events are avoided thanks to the automated Smartfreezer action.

Selective selection

Management of individual samples during the loading and unloading phase.

- +

Show more

Loading and unloading is carried out individually for each ampoule, which prevents the samples stored in the device from being exposed to unnecessary thermal stress.

Each ampoule must be labeled with a unique code (barcode, dot code); the same code is assigned by the software in the device to identify the sample in the storage compartment.

Maximum connectivity

Real-time connection to any laboratory management system (LIMS).

- +

Show more

The Smartfreezer® Suite software is web-based and allows the user to send commands to the automation and interact with the laboratory information system, ensuring full traceability of users and activities.

The device is always able to connect to the LIMS to exchange information about loading and unloading operations. The management of sensitive clinical data related to the samples is fully delegated to the LIMS.

Storage security and safety devices

The ampoules are protected against harmful heating events.

- +

Show more

Extensive product studies have confirmed the ability of the device to ensure optimal preservation of stored samples. The use of Smartfreezer is a guarantee of safety and correct operation in biobanks.

- UPS integrated in the device

- Liquid nitrogen for the backup system in the event of a blocked filling valve

- Compressed air backup system

- Thermal rack to keep samples at a stable temperature during loading and unloading and to avoid thermal stress

Full traceability

Full traceability of the operations carried out on the appliance.

- +

Show more

Access to the system requires a user name and password. All actions performed by the user are recorded in a LOG file, which makes it possible to determine the exact sequence of all activities at any time. The number of different access levels is freely selectable. Access rights can be configured individually by the administrator, whereby different users can be granted or revoked authorizations for the execution of each individual process.

Exact identification of samples

Automatic reading of ampoule codes during loading and unloading.

- +

Show more

The device is equipped with an internal barcode reader to identify the samples and a touchscreen PC for easy and intuitive operation by the user.

Nitrogen supply

Independent system for handling liquid nitrogen, daily refilling is carried out independently.

- +

Show more

The samples are stored in nitrogen gas, which not only provides the safest conditions, but also prevents the risk of cross-contamination between samples. The guaranteed temperature range is -180° C to -150 °C.

Two versions of Smartfreezer EVO and EVO LAB

Basic research as well as application, clinical and diagnostic areas require a wide range of product applications. Two different versions of SMARTFREEZER® have therefore been developed.

Depending on customer requirements, versions with different capacities can be provided. The diameter of the holes for holding the ampoules is customized. Each Smartfreezer version is designed to hold a single ampoule capacity.

* PS = buffer disk **The V 180.20 model can also hold ampoules of 3 ml (total capacity 9000) and 4.5 ml (total capacity 7500). Please note - Each model can only hold one ampoule size.

Product data sheet as PDFLet us advise you

and we will discuss your requirements, costs and anything else you would like to know in an informal, no-obligation meeting.

Benefit from our many years of project experience in almost all industries and receive ideal solution proposals for your individual application. Our aim is to support you in continuously improving the quality of your products.

Why not contact us now?

0721 - 62 69 08 50

Our experience in the cryopreservation of biological samples

Angelantoni Life Science has developed the only fully automated solution in the cryogenics market that eliminates the risks and complications associated with the storage and retrieval of samples stored at cryogenic temperatures. Manual handling is not only prone to errors when loading and unloading samples, but can also be responsible for exposing samples to temperatures that are detrimental to their usability.

The ALS team's expertise in the field of biological cryopreservation has led to a proper appreciation of the importance of any biological samples in terms of the time, labor, research and money invested in each project. This involves overcoming the obstacles of storage techniques, as the biological materials to be processed contain variable water concentrations that affect the freezing stages. Cells are unstable at room temperature and thermal stress leads to irreversible decay. Since cryopreservation processes work with biological matter, they are extremely heterogeneous, which naturally means that there is no universal freeze/thaw curve.

Smartfreezer® EVO and EVO LAB ensure maximum safety, both for the storage of samples and for the operating personnel.

All versions of the Smartfeezer® EVO series are certified according to the Medical Device Directive 93/42/EEC and its subsequent amendments - a unique commitment by the company to high quality and reliable products that guarantee maximum safety in the storage of samples used in clinical and diagnostic procedures.