- Home

- en

- datalogger-monitoring-systems

- msr-applications

- performance

- impacts-of-vibration

Vibration detectives at work

Author: Sahel El Nadeim, Senior Quality Engineer, u-blox

During the electronic functional testing of GPS receiver modules, vibrations from the test equipment can have a major impact on the measured values. To prevent their influence, they must first be localized and quantified. This is where the MSR vibration data loggers can help.

The MSR data loggers are used by u-blox AG, based in Thalwil, Zurich, which is one of the world's leading providers of position detection and mobile communications technologies for automotive, industrial and consumer goods applications. The chips and modules used in the systems developed for this purpose must be subjected to a wide range of practical tests in which vibrations can occur as disruptive influences.

Vibrations: where, how, how strong?

The MSR165 data logger makes it quick and easy to find out where vibrations occur and what their nature is. It is also possible to quantify how strong the influences are and how strong they may be before the measurement is impaired.

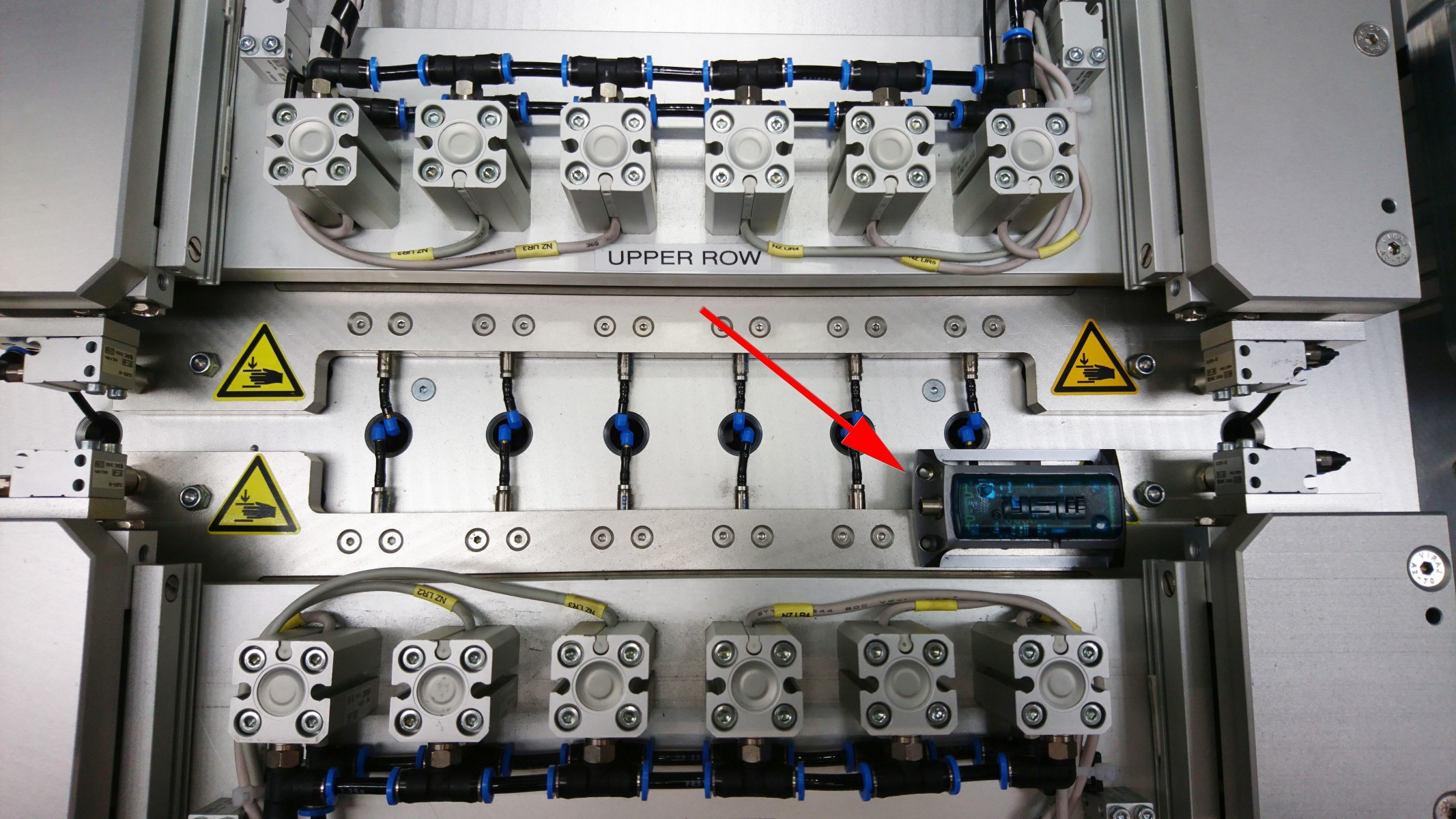

The test system used consists of two separate rows of module fixtures, one of which is in test mode while the other is being loaded or unloaded. Robot arms insert the modules to be tested individually into the holders, which are then sealed with a compressed air device for the electrical function test. After the test, the holders are opened again using compressed air and the modules are removed again using the robot arm.

All of these mechanical processes generate vibrations with different frequencies and amplitudes, with these occurring to different degrees at different points in the respective axis directions. Some of the electronic measurements carried out can be negatively affected by certain types of vibration, as the modules contain vibration-sensitive components such as quartz crystals for oscillators. Since modules are tested in one test fixture at a time while filling/emptying or opening/closing the other fixture, the vibrations of one set of fixtures can affect the measurement results of the other set.

Miniature data loggers provide good detective services

The MSR165 miniature data loggers used to record the vibrations in the module mounting rows of the test systems are specialized for applications in vibration, shock and vibration detection. Their core sensor element is a high-resolution 3-axis digital accelerometer. With this sensor element, the logger can record shock loads or vibrations of ±15 g up to 1,600 times per second in the three spatial axes, but an extended measuring range of ±200 g (g = acceleration due to gravity 9.81 m/s2) is also available. The latter measuring range would always be useful when it comes to recording loads in which very large forces suddenly occur. Temperature, humidity, pressure and light intensity could also be measured and recorded in parallel with the vibration measurement.

The data recording of the digital 3-axis accelerometer starts either when an acceleration threshold value is exceeded or at a time specified by the user.

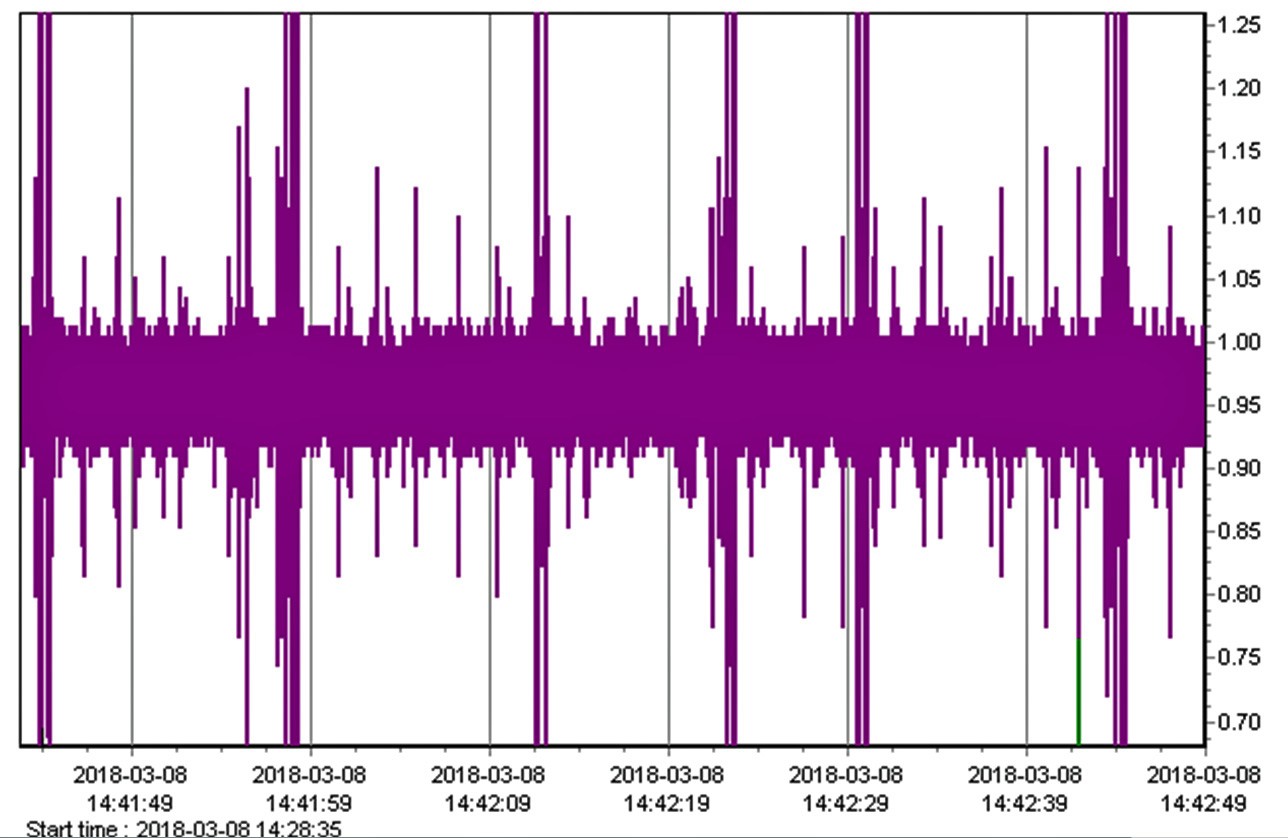

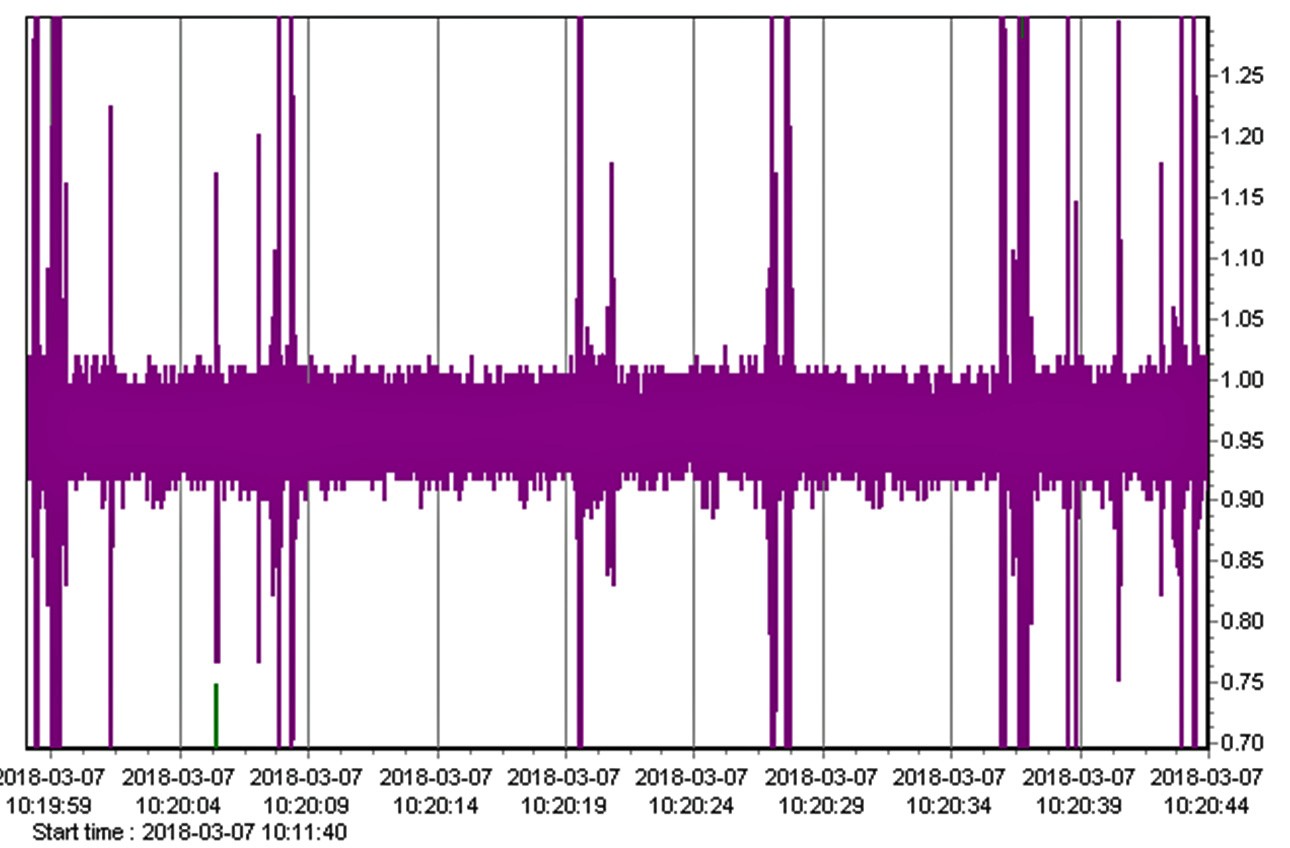

In this specific case, the data collected showed that vibrations can be measured in one of the recording rows during the electronic testing of the modules, which occur during the loading and unloading of the other recording row. The amplitude, frequency and affected vibration axis can be precisely identified. A high sampling rate was required for this measurement, which is available with the MSR165 at 1600 Hz.

A previous measurement, in which the MSR165 was also used as a vibration logger, confirmed that such vibrations have a negative effect on the measured parameters. By applying vibration-reducing measures, test failures due to vibrations can now be minimized.