- Home

- en

- datalogger-monitoring-systems

- msr-applications

- performance

- production-optimisation

MSR data loggers: all-rounders in a small format

The thumb-sized MSR165 mini data logger can be used in many areas of physical and electrical measurement technology. It can be used to record 3-axis acceleration, air pressure, humidity, temperature, light and any other electrical voltage values. Here is an application example from industry that shows how useful these small measurement data recorders can be.

At its St. Wendel site, Fresenius Medical Care produces peritoneal dialysis systems that can be used to perform very gentle blood washing on patients. Special plastic valves are required for these highly complex medical electronic devices, which have to be manufactured and assembled in a clean room in accordance with the applicable regulations. In the production machine used for the assembly work, these valves are transported on workpiece carriers that are milled from solid polyethylene terephthalate (PET) material. However, the permanent mechanical stresses have led to signs of wear on the workpiece carriers, so it was decided to develop a new and more resistant design.

Precise detection of dynamic mechanical loads

Versatile use in industry: the MSR165 data logger measures vibrations on a CNC lathe, for example. The basis for the development of a new variant of the workpiece carriers was initially a comprehensive series of measurements carried out by Daniel Klein, a student at the Chair of Polymer Materials at Saarland University, as part of his Bachelor's thesis. Initially, workshop data and load measurements served as the basis for the analysis and evaluation of the existing solution. These were evaluated and converted into strain stresses using the finite element method (FEM). This provided information on the suitability of the current workpiece carriers with regard to their requirements in operation and thus provided basic data for developing a further optimized solution. In this context, it was also important to measure the dynamic mechanical loads to which the workpiece carriers are subjected. For this purpose, an MSR165 B8THPA data logger from the Swiss manufacturer MSR Electronics was screwed onto a workpiece carrier in the series of measurements and - like the other workpiece carriers with the valves - inserted into the real production sequence of the machines.

Recording acceleration 1600 times per second

The logger of the MSR165 series is a data acquisition/storage system that works autonomously in long-term operation and records data on microSD memory cards. The current version is equipped with a high-resolution and very sensitive 3-axis digital accelerometer. Thanks to its small format (39 x 23 x 72 mm, dimensions approx. 64 g) and the ability to record accelerations in three axes, the logger is very well suited to the task at hand at Fresenius Medical Care.

The sensors are built into an anodized, waterproof aluminium housing. The robust logger is ultimately able to measure accelerations (shocks, vibrations) up to 1600 times per second in all three axes, with a digital measurement resolution of 13 bits. Temperature, humidity, pressure and light can be recorded simultaneously. The memory capacity of the logger is over 2 million measured values, which is sufficient to record over 10,000 shocks. The MSR165 thus meets the requirement of many engineers for a measuring frequency of over 1 kHz in the shock measurement range, which incidentally is possible up to maximum accelerations of +/-15 g - a measuring range that is very often required by users. And as it is often necessary to find out the history of the "shock" during a g-analysis, the logger can record 32 measured values before the actual event. The user then not only knows that a hard shock has occurred, but also recognizes the exact course of the shock in the three spatial axes.

The lithium-polymer battery with a capacity of 900 mAh could ultimately be used to monitor acceleration for up to six months if the measurement rate is adjusted accordingly, which in this specific case was of course just as unnecessary as the recording of temperature, humidity, pressure, light or analog input voltages. If you need a larger memory, you can also use a microSD card (≥4GB) to increase the capacity of the MSR logger to over 1 billion measured values. measured values.

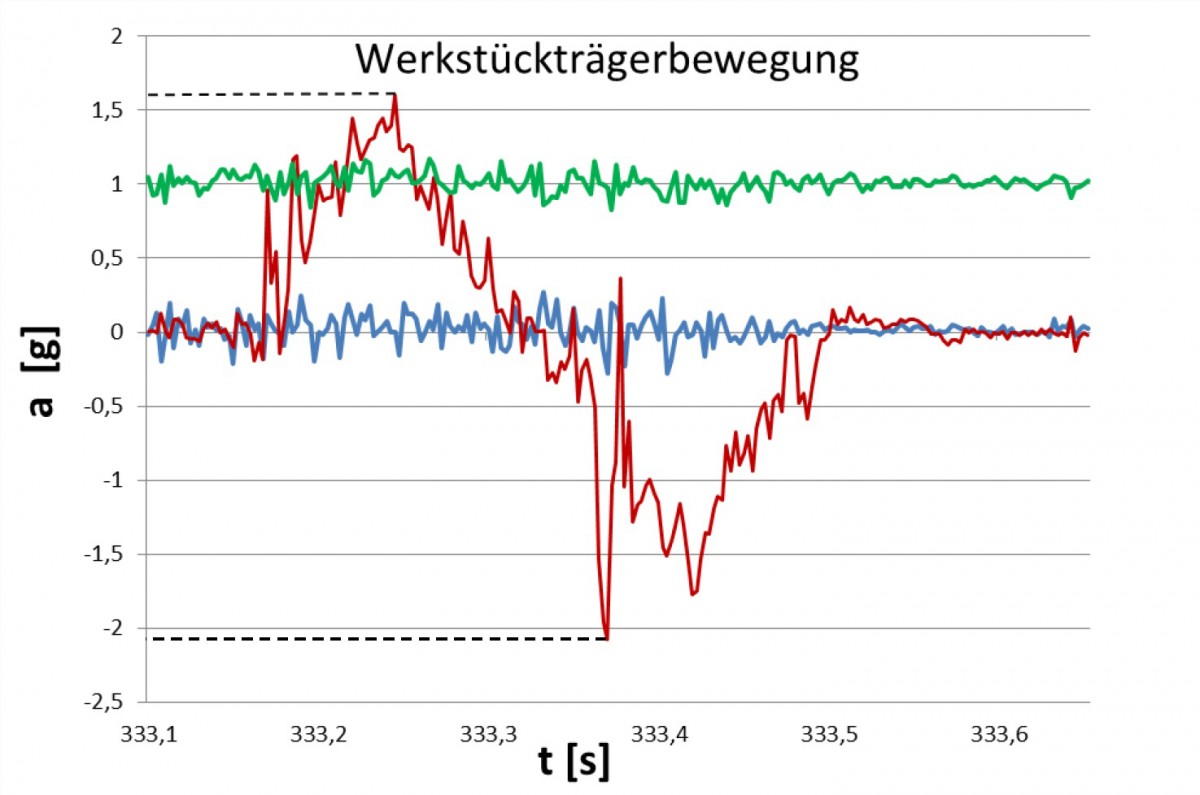

Revealed: wear and tear due to shock-like accelerations

As the strain-related design of plastic components is in principle independent of the type of load and duration, it was sufficient in this case to evaluate the maximum (impact) loads with the logger when examining the workpiece carriers. During the series of measurements, this made it possible to identify the acceleration curve during the jerky advancement of the workpiece carriers in the automatic processing machine. The accelerations here are usually in the +/-2 g range. Vibrations and impacts that had previously gone unnoticed by camera recordings were detected in this way.

Ultimately, only the MSR data logger made it possible to precisely quantify the dynamic loads during operation. In this way, operating problems caused by signs of wear due to the shape and mass of the workpiece carriers were discovered. They can be avoided in future, as can maintenance work resulting from the signs of wear, by using an optimized physical design for new workpiece carriers in the future.