- Home

- en

- datalogger-monitoring-systems

- msr-applications

- transport

- damage-during-transport

Reliable proof of transport damage

In globalized markets, industrial goods and goods of all kinds have to be shipped all over the world. And a lot can happen during such goods transports - especially when they span several continents: High temperatures, unacceptable humidity levels or mechanical shock events are just a few examples of damage incidents that cause annoyance as well as expense. However, compact miniature data loggers can help to precisely analyze the causes of transport damage or identify those responsible.

If damage has occurred due to unfavorable environmental or transport conditions, it is possible - if important environmental parameters were recorded during transport - to determine retrospectively what happened and when. Some companies even stipulate certain environmental specifications for the shipment of sensitive goods, which must of course be monitored. If precise proof of damage can be provided later, this always makes it easier to answer liability and quality assurance questions or at least provides information on how problematic transport circumstances can be avoided in the future.

Getting to the bottom of transport problems

The Swiss company Belimo Automation AG, which has assembled circuit boards for heating, ventilation and air conditioning control systems produced in China and the Philippines, has also had to deal with problematic transportation circumstances. Once a week, a standard container fully loaded with the company's own products arrives in Switzerland after a sea voyage lasting around six weeks and subsequent land transportation. The PCBs housed in the containers in cardboard boxes and blister packs are particularly sensitive to the effects of moisture. In particular, it is the slide switches and plug connectors on the circuit boards that would be damaged by excessive moisture or even direct exposure to water.

This is exactly the kind of case that occurred some time ago, and so Belimo decided to use the MSR145 mini data loggers already known in the in-house research department to monitor and document the temperature and humidity conditions prevailing during transportation and to have them packed in the transport containers. This is because in the event of further damage, the company wants to be able to prove this to the logistics company responsible.

Small loggers do valuable work

The MSR145 data loggers, which are only the size of a thumb, store over 2 million measured values - with an optional microSD card even over a billion measured values - and are very well suited for long-term measurements during transportation. They are able to simultaneously measure and store the five important physical parameters of temperature, humidity, air pressure, position/3-axis acceleration and light. All measured values can later be transferred to a computer for data analysis via USB interface or microSD card and evaluated in detail using the "MSR Viewer" software. These loggers are available in various versions, which can also be customized. Analog inputs can also make it possible to connect individual, external sensors for a wide range of measurement tasks (e.g. CO2, conductivity, pH, etc.).

In this specific case, only the "humidity" and "temperature" parameters need to be recorded during the sea/land transportation of Belimo products from the Far East to Europe. The MSR data loggers could do this every second, but here the programming, which takes place at the company headquarters in Hinwil, specifies a recording interval of one minute, which is completely sufficient.

When the containers are loaded, a trained employee packs a logger together with the PCBs and places this box at the top of the container. The "Start" button on the logger must first be pressed to begin the measurement cycle.

Problems diagnosed to the minute

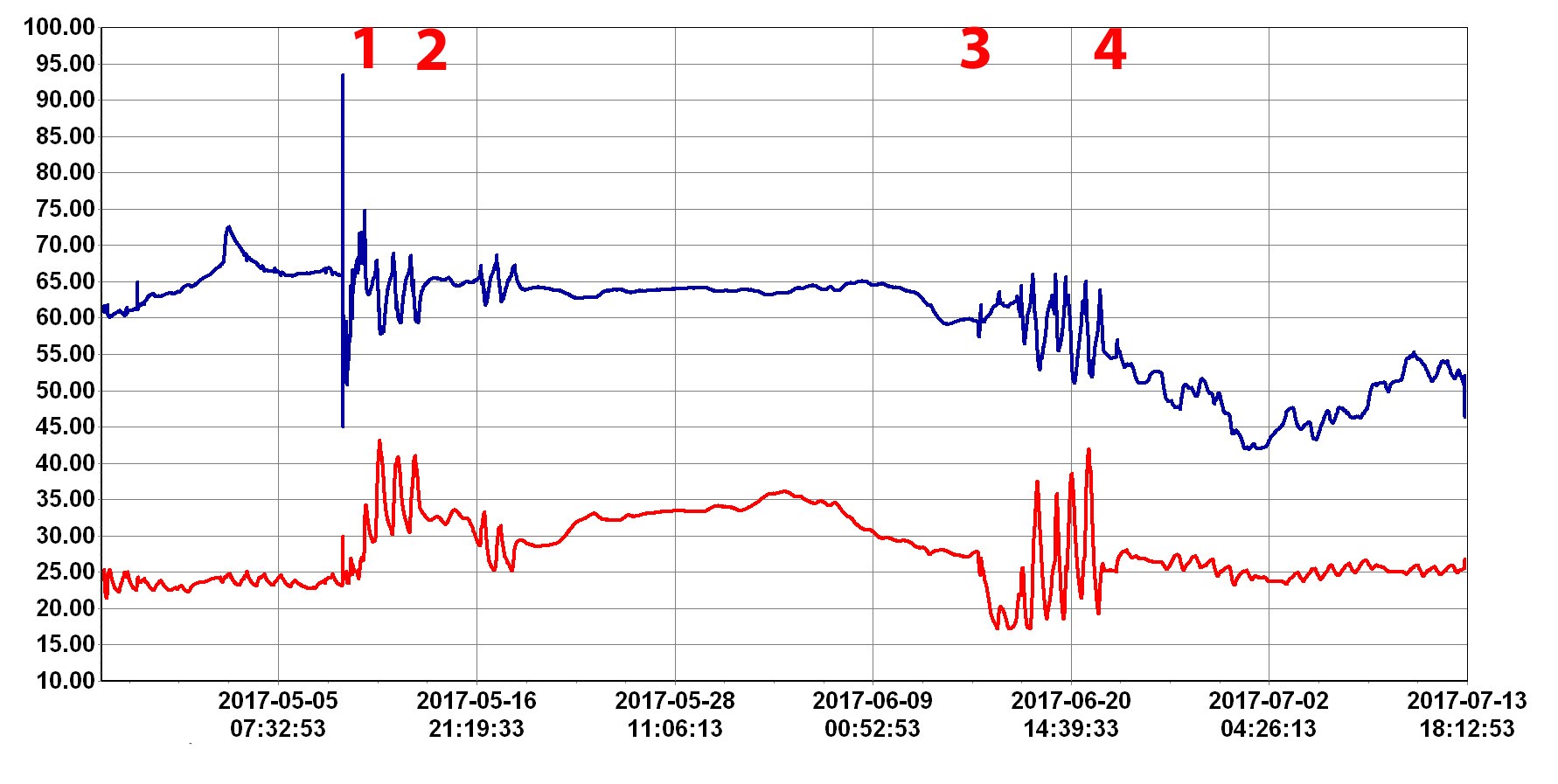

After transportation and upon arrival and opening of the container at Belimo in Hinwil, the data logger is removed and its data record is examined using the "MSR Viewer" evaluation software. The measured temperature and humidity values recorded at 1-minute intervals throughout the entire transport are now displayed in a clear diagram, with the time at which the respective values were recorded being readable to the second (Fig. 4). The logger data can ultimately be used to precisely determine whether or when exactly damage has occurred. In this specific case, the temperature value is of secondary importance, as the PCBs are specified for storage temperatures of up to 50 degrees C anyway.

"In this way, we can find out exactly on which section of a transport route a temperature overload or moisture exposure may have occurred. It is then relatively easy to identify the logistics company responsible for this based on the time," explains Beat Kuster, who is jointly responsible for lifecycle issues in electronics development at Belimo. "We are therefore very satisfied with the loggers. In the past, we had a major incident where we had to remove all the circuit boards from their blister packaging, check them and dry them again because they had been exposed to water."

The small MSR145 data loggers - Belimo now has around 30 of them in continuous use - cannot ultimately prevent transport damage or impairment. However, they can help logistics companies to handle the goods entrusted to them more carefully and, in the event of damage, to precisely identify the party responsible. The detailed analyses of the data loggers can also provide significant assistance in legal disputes.