- Home

- en

- datalogger-monitoring-systems

- senseanywhere-applications

- gastronomy-hotel-industry

Temperature monitoring in the catering and hotel industry

Whether in individual catering, system catering or communal catering, in the hotel industry or catering, the correct storage of food is essential in all these areas. The temperature control of food in particular plays a decisive role, as perishable food should remain fresh for as long as possible. Microorganisms multiply more slowly at low temperatures, which delays the multiplication of pathogenic bacteria. Companies that process critical foods are obliged to maintain the cold chain and document the temperatures as part of the inspection.

What needs to be monitored in the food service industry?

Whether it's the cold room, refrigerated counter, refrigerator or freezer, whether in the kitchen, cellar or warehouse, the cold chain and therefore the marketability of the food must be maintained.

As frozen goods must be stored at -18 °C, meat products at +4 °C and fish, minced meat and poultry at a maximum of +2 °C (DIN 10508), and fruit, vegetables and other foods at other temperatures, several storage areas are generally the norm. In large companies, goods worth several thousand euros are often stored; discarding food due to incorrect temperature conditions therefore has painful financial consequences.

- +

DIN 10508: Food hygiene - Temperatures for food

The tables in DIN 10508 with maximum temperatures for deep-frozen, frozen and chilled foods and minimum temperatures for foods kept hot provide an overview of the legally binding temperatures specified or recommended by the working group for the various food categories.

- +

Overview - Storage temperature of food

Products Storage temperature max. core temperature Fresh meat, sliced salads, meat preparations and products (sausage), etc. +4 °C +7 °C Fresh poultry, poultry meat preparations, minced meat, game +2 °C +4 °C Fresh fish in melting ice or 0 °C +2 °C Offal +2 °C +3 °C Milk, dairy products, butter, cheese +4 °C +10 °C Pasteurized egg products +2 °C +4 °C Baked goods and fruit products requiring refrigeration, delicatessen products +4 °C +7 °C Eggs after the 18th day of laying +5 °C +8 °C Chopped fruit and vegetables +4 °C +7 °C Frozen food and ice cream -18 °C -15 °C

Solutions for the control & documentation of temperatures

1. Temperature documentation with a temperature list

The minimum requirement for monitoring temperatures in a catering business is the use of a min-max therm ometer, which displays the minimum and maximum temperature between two readings. However, such a min-max thermometer also involves inconveniences and risks. On the one hand, the thermometer must be read very consistently every day and entered in a list that must be maintained and archived. Secondly, the person entrusted with this task must be very reliable and trustworthy. The decisive disadvantage of a min-max thermometer, however, is the lack of a reliable alarm in the event of a limit value being exceeded; and preferably before any damage has occurred!

2. Automated temperature control in the catering industry

Nothing could be simpler. With our system for fully automated temperature monitoring, you have the temperatures in your business firmly under control. The system is very easy to install and extremely intuitive to use. View the continuously recorded data at a glance - at work, at home or on the move. Specify temperature limits and receive a warning on your PC or by e-mail or text message if these limits are exceeded - the only way to prevent damage in good time. If required, the system can generate fully automatic reports for documentation and possible submission to inspectors.

And the best thing about it: you have no work at all. You place the measuring systems at the points that need to be monitored. After a simple and short set-up phase, the monitoring system runs completely automatically and reliably and only reports when it needs your attention.

3. Temperature logger for catering establishments

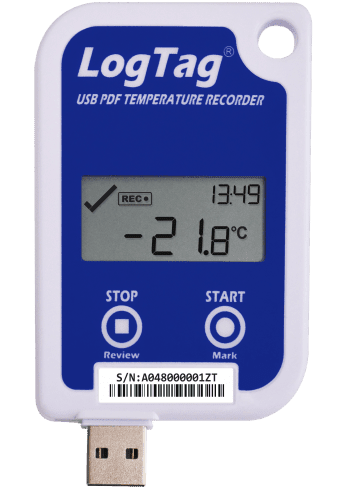

A temperature logger is a mobile, battery-operated measuring device that measures the temperature in the air or in another medium at specific time intervals. The data is either stored on the measuring device itself or transmitted to a data memory via a transmitter.

We offer temperature loggers from the LogTag series for temperature measurement in the catering industry. The data is stored directly on the device. The LogTag data loggers can be read out manually. You receive alarms directly when you are on site.

Test our temperature monitoring system free of charge!

Test the demo kit free of charge and without obligation within one week. Test the advantages and possibilities offered by SenseAnywhere at your leisure. Directly on your premises with your conditions and your data. Measure the temperatures in your pharmacy, trigger alarms, create documentation and familiarize yourself with the system.

The demo kit contains two data loggers, an access point and everything you need to get the system up and running on your premises and record your own temperature and humidity data.

With our temperature monitoring solutions, the temperatures in your pharmacy can be documented electronically and error-free.

Whether manually reading out a data logger or fully automatically transferring the recorded measurement data to the cloud. The documentation of your pharmacy's temperatures can be viewed at any time and historical data can be easily accessed.

Are you subject to a duty of proof? For documentation purposes or as proof, you can create and save a report with all relevant data at any time or have a report sent to you fully automatically by email.