- Home

- en

- biomedical

- ultra-low-temperature-freezer-minus-80-degree

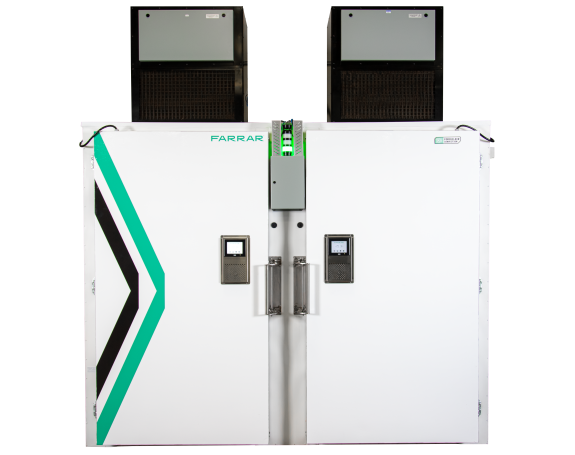

FARRAR™ ULC Cooling Solutions with Forced Air Cooling

Together with FARRAR, we offer you unique solutions for ultra-low-temperature storage. FARRAR is a pioneer in forced air convection cooling, ensuring maximum performance, safety, and efficiency in cooling storage. Specifically designed for pharmaceutical and biotechnological applications, the Ultra-Low Chamber ULC-190, new ULC-259, and

ULC-311 are the only -20 °C to -80 °C and +2°C to +8°C freezers with forced air cooling for ultra-low temperatures available in today's market.

ULT Storage under Optimal Conditions

Especially suitable for large product volumes, our FARRAR cooling chambers are designed for quick, efficient, and sustainable cooling storage.

With a capacity ranging from 5,380 to 8,806 liters, these solutions contribute to the efficient utilization of available space, requiring only 4.36 square meters. The devices offer unparalleled temperature homogeneity with an accuracy of +/-3.0 °C. Additionally, they feature fully redundant systems (control, cooling, airflow) and boast the industry's fastest temperature recovery.

Key Features at a Glance:

- Integrated complete redundancy (cooling, control, electrical)

- Best temperature uniformity on the market (+/- 3.0 °C)

- Low temperature deviation (+/- 1 °C)

- Forced air cooling for a wide temperature range

- Forced air convection for rapid cooling

- Universal suitability for all container sizes and optional rack/shelving system

What Do Our FARRAR Freezing Solutions Offer?

FARRAR™ is a pioneer in forced air convection cooling to address the challenge of preserving and storing biological and tissue-donating samples and materials. The Ultra-Low Chamber (ULC-190), the Ultra-Low Chamber "Pallet" (ULC-311), and the newly introduced ULC-259 have been specifically designed for biotechnological applications and are the only freezers available on the market with forced air cooling at ultra-low temperatures from -20 to -80 °C.

Exceptionally High Capacity

Designed as a reach-in solution, the chamber has a capacity of up to 8,806 liters within a few square meters. Compared to conventional freezers, you save 50% of the floor space.

Eliminates the Need for a Backup Freezer

Integrated, fully redundant systems (control, cooling, airflow, and power).

Unparalleled Metrological Performance

The exceptionally precise temperature uniformity at any set temperature ensures that you can rely on better than +/-3 °C accuracy throughout the ULC, whether the chamber temperature is -20 °C or -80 °C. Additionally, the ULC has the industry's fastest temperature recovery, meaning it reaches the desired temperature 10 times faster after the door is opened, ensuring product integrity.

Unique Forced Air Convection Cooling

The forced air system rapidly exchanges air in the chamber instead of relying on natural convection to displace warm air in the chamber. These devices meet the best ULT freezer standards on the market today in terms of energy efficiency, significantly surpassing them in uniformity and temperature recovery after the door is opened. Finally, the chambers can be easily adapted to operational process intensification measures due to their self-contained cooling systems, reducing handling and steps.

Economically Efficient Operation

The FARRAR devices have been developed with a strong focus on energy efficiency and achieve an extremely low energy consumption of 0.33 kWh/cu.ft.

Automatic Defrost Function

Never worry about having to take devices out of operation for manual defrosting again.

A Real Alternative to Freezing Rooms and Rows of Refrigerators

Our offerings provide an alternative to traditional large freezing farms for the production of medicines, vaccines, and other biological products, addressing an unmet need for flexible, affordable, and efficient cold processing and storage.

- +

What Is Air Convection Cooling

In the field of refrigeration technology, air convection means that air is pushed or forced into the cooling area using a fan or blower unit. This results in the even distribution of air throughout the refrigerator or cooling chamber.

The function is quite simple: The fan or blower draws in air and pushes it into the cooling space, creating a continuous movement of air that ensures cold air reaches all products. This is important to ensure that all products in the refrigerator or cooling chamber are uniformly cooled.

Forced air technology has several advantages. Firstly, it ensures that the temperature inside the refrigerator or cooling chamber is consistent everywhere, avoiding temperature differences that could cause some products to become too warm or too cold. Secondly, the generated airflow helps dissipate heat from the products, leading to faster and more efficient cooling.

In short, forced air ensures that cold air is evenly distributed in the refrigerator or cooling chamber to effectively cool all products and maintain the desired temperature.

- +

What Are the Benefits of Circulation Cooling

Uniform Temperature Distribution: The generated airflow improves the distribution of cold air in the cooling space, resulting in uniform cooling of all products in the refrigerator or cooling chamber. It prevents temperature differences and hotspots, enhancing the consistency of cooling conditions.

Efficient Cooling: The generated airflow helps efficiently dissipate heat from the products. The cooled air surrounds the products and carries away heat, leading to faster cooling and a stable cooling process.

Rapid Temperature Stabilization: The use of forced air enables quick restoration of the desired target temperature after opening the door or placing products inside. The airflow helps rapidly restore the temperature inside the refrigerator and minimizes temperature fluctuations.

Improved Product Protection: Uniform cooling and efficient heat dissipation provide optimal product protection. It prevents specific areas from becoming too hot or too cold, ensuring product quality and longevity.

Energy Efficiency: Using forced air in refrigeration systems can optimize energy consumption. Targeted air distribution and circulation allow the refrigerator to work more efficiently and reduce energy demand.

Overall, forced air technology contributes to achieving better performance, stability, and efficiency in cooling, which is crucial for storing sensitive products in the pharmaceutical industry or other industries.

Performance Data, Cooling System & Controller

| Temperature Range | -20 °C to -80 ˚C and +2°C to +8°C |

| Temperature Accuracy | +/- 1.0 ˚C |

| Temperature Uniformity | +/- 3.0 ˚C (empty chamber) |

| Warranty | 1 year on installed parts |

| Evaporator | 2x Circulation Cooling |

| Condenser | 2x Circulation Cooling or 2x Water Cooling |

| Regulation Valve | Electronic |

| High Temperature Stage / Low Temperature Stage | R-449A / R-508B |

| Air-Cooled Condenser | +18 °C to +30 °C |

| Water-Cooled Condenser |

Tower Water 29.5 °C |

| Operating Requirements | Chilled Water 7.2 °C, maximum flow rate 13.25 l/min |

| Temperature Controller | 2x Microprocessor |

| Displays (145 mm) | 2x LCD |

| Modbus TCP/IP | Communication Protocol |

| (Remote) Alarming | Temperature Limits (high/low), open doors, power interruption |

| Dry Contacts | Standard (C, NO, NC) |

FARRAR ULC-190

| ULC | |

|---|---|

| Chamber Volume | 5,380 L |

| Footprint | 4.36 m² |

| Interior Dimensions |

(W x D x H)2,794 x 965 x 2,286 mm |

| Exterior Dimensions | (W x D x H) 3,098 x 1,448 x 3,632 mm |

FARRAR ULC-259

| ULC | |

|---|---|

| Chamber Volume | 7,334 L |

| Footprint | 5.17 m² |

| Interior Dimensions | (W x D x H) 3,073.4 x 1,371.6 x 1,743.0 mm |

| Exterior Dimensions | (W x D x H) 3,381.3 x 1,936.7 x 3,232.1 mm |

FARRAR ULC-311

| ULC | |

|---|---|

| Chamber Volume | 8,806 L |

| Footprint | 6.28 m² |

| Interior Dimensions | (W x D x H) 2,946 x 1,372 x 2,210 mm |

| Exterior Dimensions | (W x D x H) 3,251 x 1,930.4 X 3,734 mm |

Services & Additional Options

- Warranty Options

- IQ/IQ Validation

- Temperature Mapping

- Shelving System and Mobile Material Handling

- Custom Programming and Qualification