- Home

- en

- test-cabinets-for-environmental-research

- chambervalidation

Climate chamber validation of temperature and humidity

The regular validation of climate chambers plays a decisive role when it comes to compliance with directives and quality standards. With our systems for the qualification of climate chambers, you can ensure the simulation of exact climate conditions.

Sensor holder for climate chamber mapping

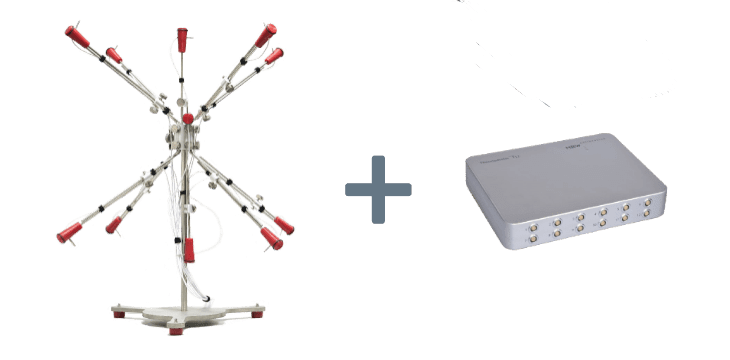

Features Kambic Spider

- 11 adjustable sensor holders

- for temperature sensors from 3 to 6 mm

- Intelligent cable routing

- Temperature range -50 to +200 °C

- Compliant with climate test standards

Product data sheet Kambic Spider

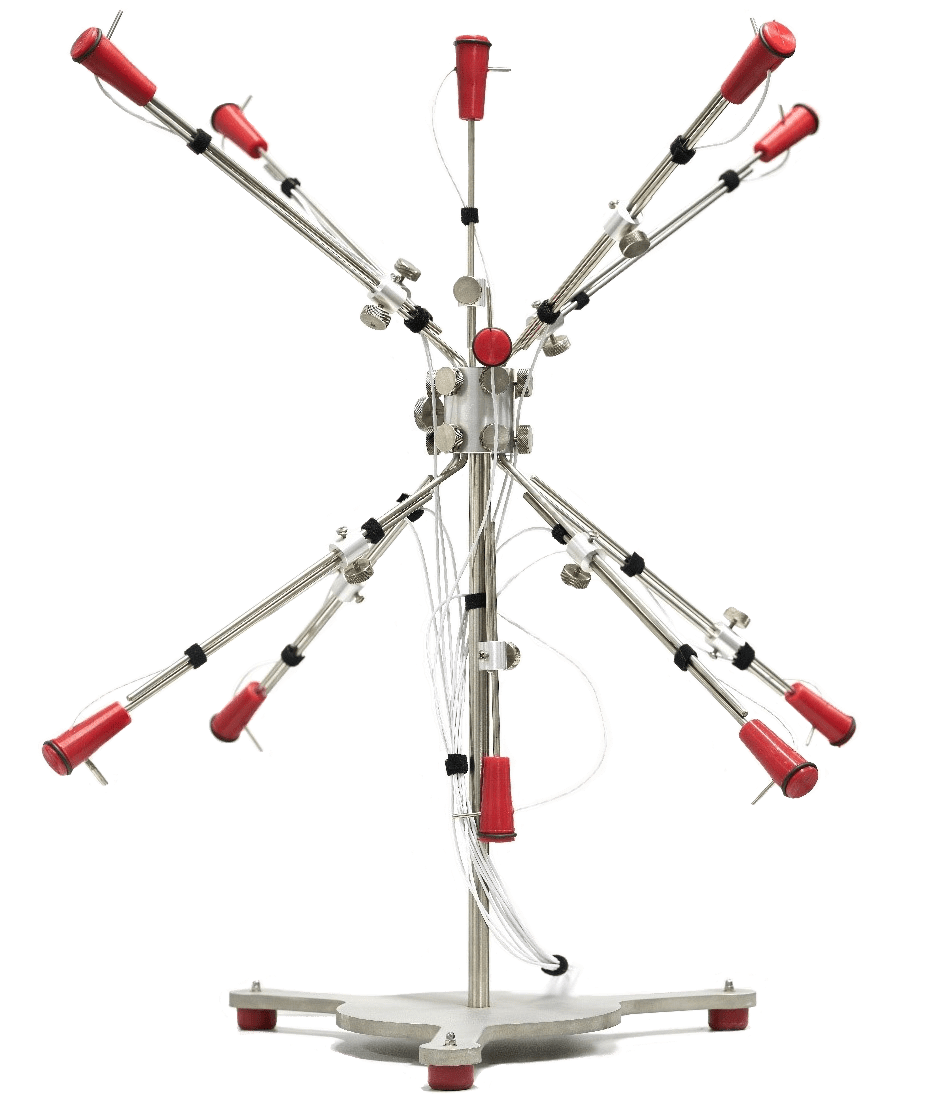

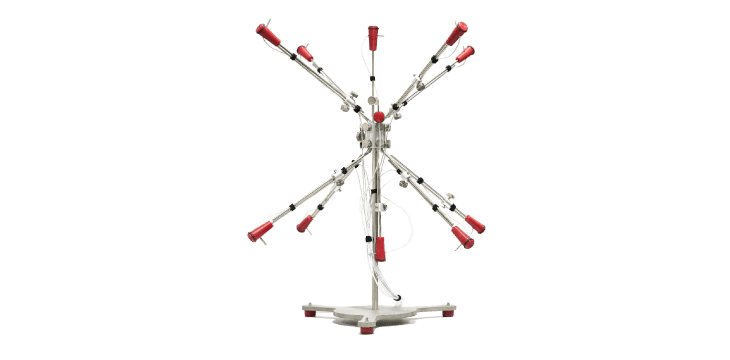

Flexible holder for temperature and humidity sensors

The mapping system has eleven sensor holders made of flexible and insulating silicone. These separate the temperature sensors from the mounting rods with intelligent cable routing. You can use temperature sensors with a diameter of 3 to 6 mm and a temperature range of -50 to +200 °C. The mounting rods are designed so that you can position temperature sensors in the upper and lower corners as well as the vertical center line of your climate chamber.

This gives you a 360° temperature and humidity profile of the chamber(s).

Humidity uniformity

In combination with a dew point hygrometer, temperature uniformity data can be combined with dew point data for relative humidity uniformity studies.

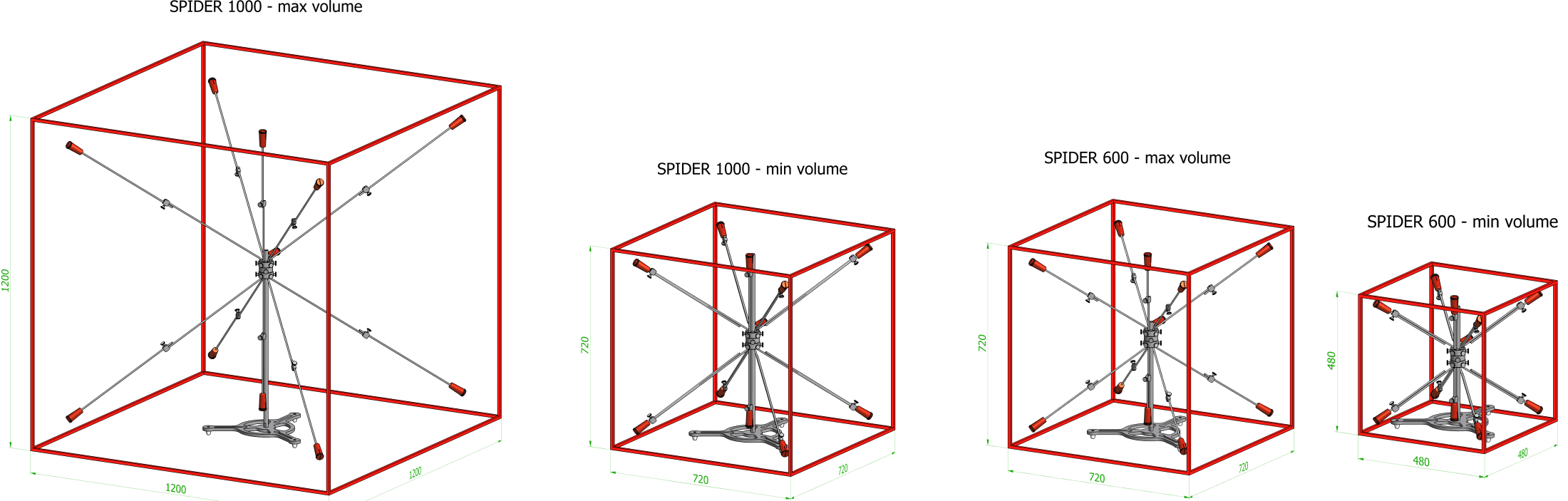

The Spider 600 version for chambers with internal dimensions up to 480 mm and the Spider 1000 version for chambers with internal dimensions up to 1200 mm.

Multi-channel temperature measuring system

The T12 is a multi-channel temperature measurement system that provides temperature data from up to 12 sensors with high precision for calibration and validation processes. It is ideal for climate chamber validation applications where temperature uniformity is a major contributor to overall uncertainty. Multiple probes of the T12 enable spatial temperature measurement to visualize the gradients within the chamber

The high precision and durability of the T12 and Pt-100 probes allows test engineers to accurately define the temperature and its distribution. In combination with a dew point mirror, the temperature data from the T12 can be combined with dew point or frost point data to define the relative humidity distribution within a test or stability chamber. This methodology is defined in test standards and guidelines such as EC60068-1, DKD-R 5-7, Euramet-cg-20 and NF X 15-140.

Properties of multi-channel thermometers

- High precision, stability and repeatability

- Integrated platinum resistance thermometer and reference resistors

- 22-bit analog-to-digital converter

- PC software for system control and data acquisition

- Pt-100 and Pt-25 versions

To the product page

MBW dew point mirror 473

The dew point mirror model 47 3 is a portable device equipped with a separate measuring head for the punctual and continuous measurement of dew point and temperature in air and gas mixtures. Based on the dew point mirror principle, the 473 provides direct and accurate humidity measurement.

The frost/dew point measurement can be combined with a multi-channel temperature measurement such as the MBW T12. With such a measurement system, spatial temperature and RH distribution can be measured, displayed and recorded for validation purposes

Dew point mirror properties

- High-precision dew point mirror technology

- Mobile measuring heads incl. temperature sensor

- Optional barometric pressure measurement

- Optional analog outputs ±10 V and 4-20 mA

- LCD color touch screen with intuitive user operation

- Verifiable calibration

Flexible system options for climate chamber validation

1. mapping system

Kambic Spider

Sensor holder for climate chamber mapping

2. mapping and temperature validation system

Kambic Spider + Thermometer T12

Sensor holder for climate chamber mapping and temperature validation system

3. complete system for temperature and humidity validation

Kambic Spider + thermometer T12 + dew point mirror 473

Complete system for temperature and humidity validation in climate chambers

Climate chamber validation

Validation of a climate chamber should be carried out regularly to achieve the required specifications and comply with laboratory or regulatory standards. Climatic chambers can be tested with or without load, depending on the type of product to be tested.During the procedure, the chamber is subjected to a functional test with calibrated instruments for humidity and temperature in relation to the actual value reached, the control stability and the spatial distribution or gradients. The choice of instrument used to measure the chamber performance affects the uncertainty associated with the chamber calibration.

These pages may also interest you