- Home

- en

- product-drying

- vacuum-dryers

CiK Solutions offers a wide range of vacuum dryers. Choose between different models from 8 liters to 130 liters volume. All models in our Kambic vacuum dryer series are easy to operate, extremely reliable, highly precise and very durable.

Kambic vacuum dryers

We offer high-performance dryers in three chamber sizes with a maximum operating temperature of 200 °C. If required, this range also provides a basis on which a variety of customer-specific modifications can be made.

Vacuum drying is a mass transfer process in which the moisture present in a substance (usually a wet solid) is removed by generating a vacuum. In the chemical process industry such as food, pharmaceuticals, agriculture, textiles, paper & pulp, etc., drying is an essential prerequisite for the removal of moisture.

Vacuum drying is generally used to dry hygroscopic and heat-sensitive substances and is based on the principle of creating a vacuum to reduce the pressure below the vapor pressure of the water. Vacuum pumps are used to reduce the pressure around the substance to be dried. This reduces the boiling point of the water inside the product and thus significantly increases the evaporation rate. The result is a significantly increased drying rate of the product.

In the pharmaceutical industry, the vacuum dryer is commonly known as a vacuum oven. The oven door is sealed airtight with a high-quality silicone seal and connected to a vacuum pump to reduce the pressure.

In addition to models for vacuum drying, we also offer drying ovens

.Drying in a vacuum up to 1 mbar with heated shelves:

- Evaporation at low temperatures

- Determination of the drying curves

- Determination of dry mass

- Pilot vacuum drying

Properties of the vacuum ovens

- Heated shelves and PID control

- Vacuum brake valve

- Valve for controlled leakage and vacuum valve

- Needle valve for inert gas inlet or outlet

- AISI 304 stainless steel chamber, polished to Ra 0.5 m with fast door closing mechanism

- and highly resistant food-safe silicone seal

- Chamber door with overpressure relief

- Protective window for monitoring the drying process

- Microprocessor control with LCD display

- 10 different automatic programs or manual control

Laboratory vacuum oven and laboratory vacuum dryer models

| VS-8 SC | VS-25 SC | VS-50 SC | VS-130 SC | |

| Volume (liters) | 8 | 25 | 50 | 130 |

| Heatable shelves | 2 | 2 | 2 | 5 |

| Temperature range | +5 to +200 °C | +5 to +200 °C | +5 to +200 °C | +5 to +200 °C |

| Wattage | 1800 watts | 2000 watts | 2500 watts | 2500 watts |

| External dimensions | 390 x 500 x 425 mm | 480 x 602 x 430 mm | 730 x 510 x 495 mm | 670 x 856 x 725 mm |

| Internal dimensions | 200 x 200 x 208 mm | 300 x 275 x 307 mm | 405 x 510 x 370 mm | 495 x 495 x 530 mm |

| Temperature stability | ±0,1 °C | ±0,1 °C | ±0,1 °C | ±0,1 °C |

Vacuum pumps

The decisive factor in vacuum drying is setting the correct vacuum. There are many different types of vacuum pumps available specifically for vacuum drying. In practice, however, two main types of pumps are used:

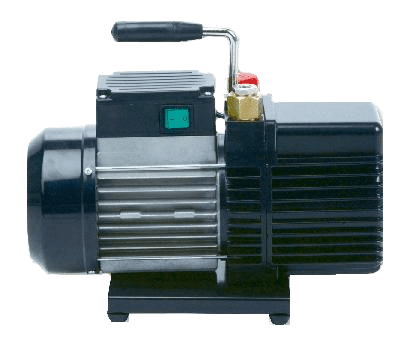

Oil vacuum pump

Features of the oil vacuum pump suitable for use in our dryer:

| Model: | RS9D |

| Capacity: | 9m3/h |

| Ultimate vacuum: | 10-2 mbar |

| Number of stages: | 2 |

Oil vacuum pumps are the most popular and inexpensive pumps. They can easily achieve a vacuum of 1 mbar or lower. With proper maintenance, they are robust and very durable. However, there are also some disadvantages. Oil vacuum pumps are usually not chemically resistant, which makes it necessary to use a vapor condenser when drying aggressive media. Otherwise, these aggressive media can damage vital parts of the pump, the oil quality can deteriorate drastically and thus require regular oil changes, and the pump must be cleaned regularly.

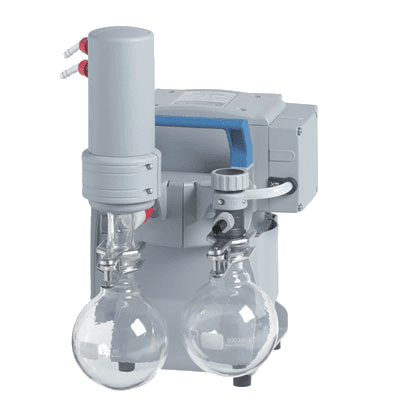

Chemical resistant diaphragm vacuum pump

Features of the chemical vacuum pump suitable for use in our dryer:

| Model: | MD4C+AK+EK |

| Capacity: | 3m3/h |

| Ultimate vacuum: | 2 mbar |

| Number of stages: | 3 |

This pump is chemically resistant and makes it possible to dry aggressive media, as the pump runs "dry" and therefore no oil change is required. This considerably extends the maintenance intervals. The diaphragm pump has a glass collection container built into the outlet section as standard, which prevents condensed liquid from entering the pump. There are also two built-in, thermally insulated glass condensers on the outlet side, which can be cooled with water and thus contribute to improved condensation and collect exhaust gases.

As the pump is not oil-lubricated, there are no oil vapors. Despite the multi-stage design, the vacuum can reach up to 2 mbar.

Further variants of the vacuum pumps can be found in our Data sheet Kambic vacuum furnace

Vacuum furnace accessories

- Calibration with certificate (3 temperatures, 10 sensors + vacuum)

- Vacuum furnace IQ/OQ documentation

- Housing made of stainless steel AISI 304 (DIN EN 10027-2 1.4301)

- Interior made of acid-resistant stainless steel AISI 316 (DIN EN 10027-2 1.4401)

- Printer for recording the process progress

- Stainless steel tube frame for positioning the dryer and vacuum pump

Customized solutions - Describe your requirements and we will make you an offer for a tailor-made system!

Well-known customers rely on laboratory solutions from Kambic

These pages may also interest you