- Home

- en

- biomedical

- walk-in_cool_rooms

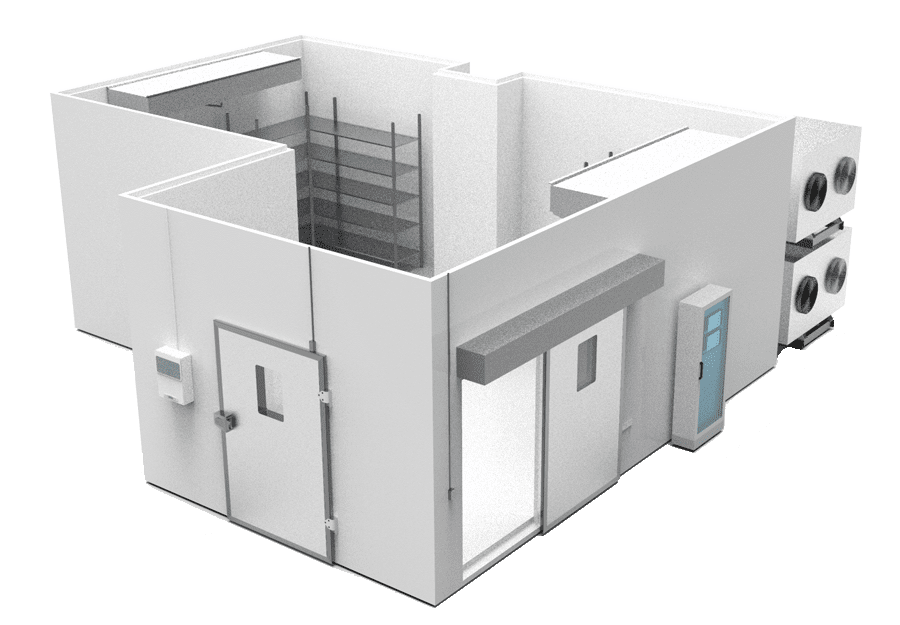

Modular Cooling Storage for the Chemical and Pharmaceutical Industry - PE Series

In collaboration with Angelantoni Life Science, we offer you a range of modular and walk-in cold rooms designed for the storage of vaccines, medications, and other products in the pharmaceutical and chemical industries, as well as healthcare. The main features of this product range are high reliability and the ability to customize the cold rooms precisely to local conditions. Our cold rooms are manufactured in compliance with applicable and necessary standards.

Features of our cold rooms:

- Quick and easy assembly

- Rounded corners inside

- Precise temperature control (light intensity and humidity upon request)

- Insulation material made of foamed polyurethane, polystyrene, or mineral wool

- Direct and indirect cooling systems

- ATEX version available upon request

- Maximum fire resistance class: A2s1d0.

Retrofit - Modernization and Overhaul as an Alternative to Buying New

Overhauling or replacing refrigeration systems, seals, and wear parts can bring new life to older solutions and save money compared to purchasing new ones. What should you consider when modernizing cold rooms, and in which cases does it make sense?

Contact us, and we will calculate the best option for your company!

![]() 0721 – 62 69 08 50

0721 – 62 69 08 50

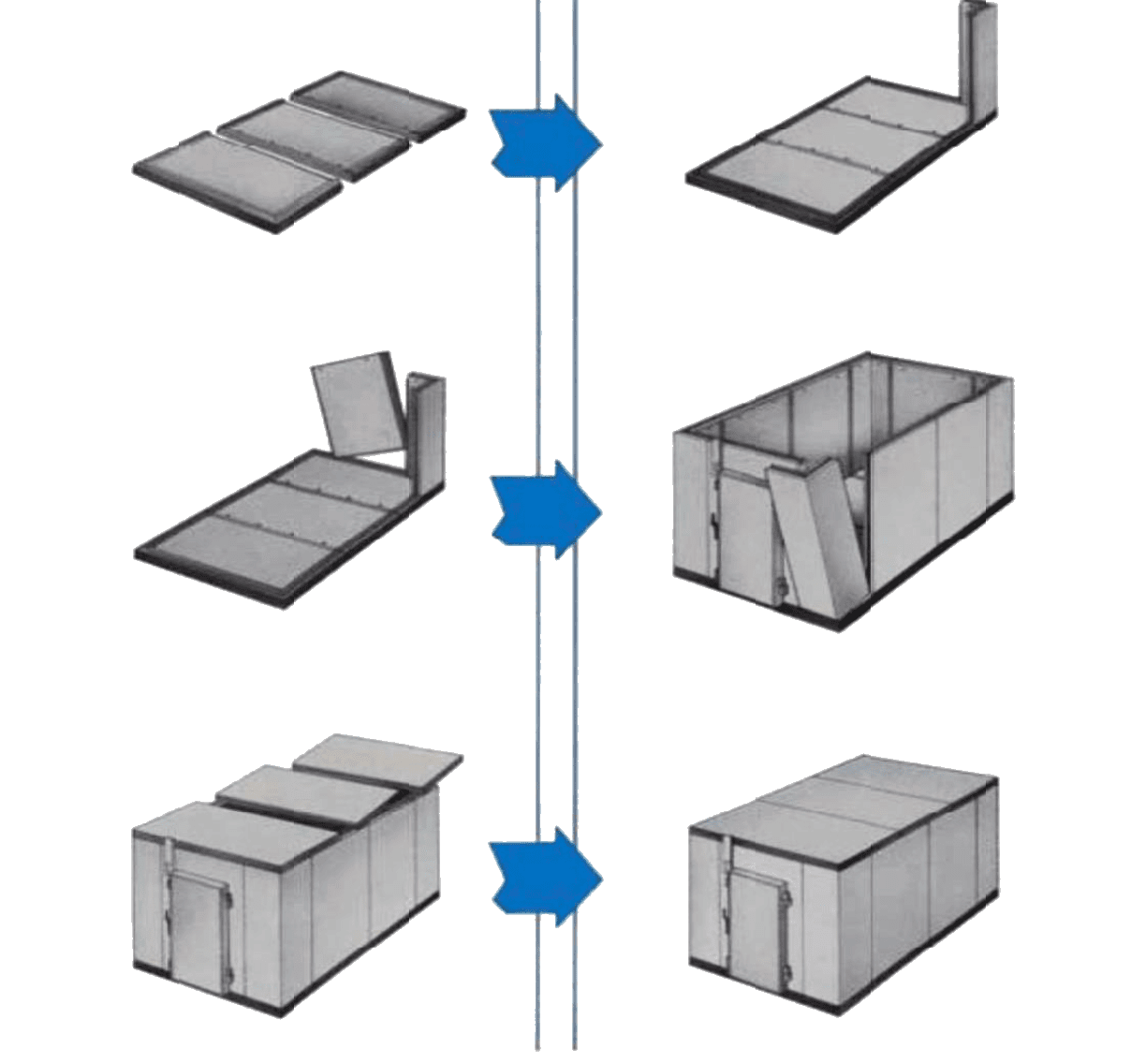

Creating a Walk-In Cold Room of the PE Series

Insulated floors with pre-painted sheet metal, aluminum diamond plate, or non-slip stainless steel.

Our floors can handle heavy loads, such as those generated by pallet jacks and forklifts. The floor is equipped with a drain to simplify cleaning and divert spilled liquids. The corners inside are rounded for easy dirt removal.

The walls consist of modular panels with a core of expanded polyurethane, polystyrene, or mineral wool and a pre-painted steel or stainless steel cladding (AISI 304 or 316). The panels are available in thicknesses ranging from 50 to 200 mm.

The service door is equipped with high-quality rubber or silicone seals and an microswitch that automatically turns off the fan when the door is opened.

On the outside, there is a lockable door with a handle that can be opened from the inside in any case. Sliding doors that open manually or automatically can be supplied complete with Airwave safety switches on request. The door frame is heated by a specially installed electrical element. Optionally, PVC protective curtains can be added to the doors to minimize heat loss when opened.

Modular Construction of Walk-In Coolers

Modular walk-in cooler with 150 mm thick panels, plastic coating inside and outside.

Dimensions: 40.50 m (L) x 8.00 m (W) x 10.20 m (H)

Sliding doors: 2 m (W) x 3 m (H) clear width, automatic opening with safety lock.

Operating temperature: -20 °C

Modular walk-in cooler with 100 mm thick panels, plastic coating inside and outside.

Dimensions: 28.00 m (L) x 11.6 m (W) x 8.5 m (H)

Sliding doors: 2 m (W) x 2.5 m (H) clear width, automatic opening with safety lock.

Operating temperature: +2 °C.

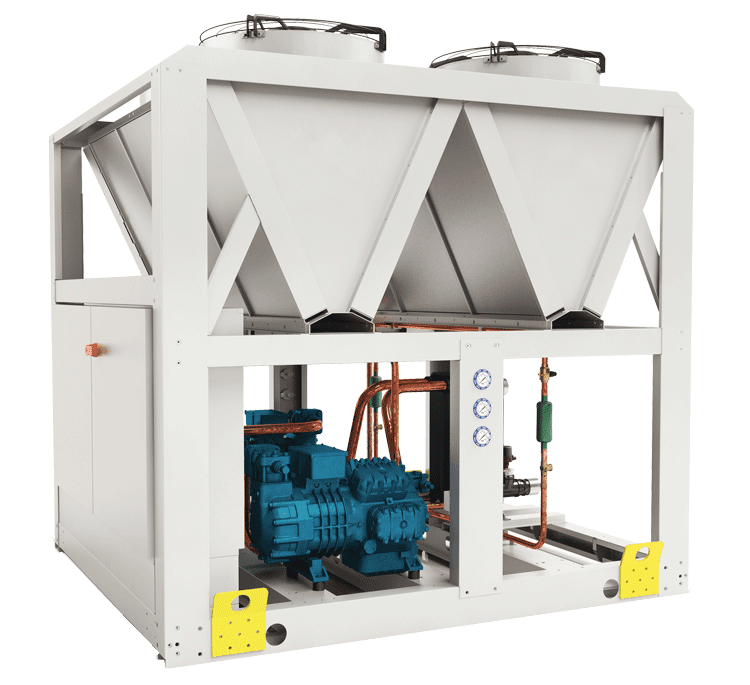

Custom Cooling Units

We design and manufacture custom cooling units to meet your specific requirements. Our systems, equipped with modern safety systems, offer lower environmental impact and significantly higher efficiency compared to older generation systems (R507/R404A).

- Heating capacity: from 10 to 2,000 kW

- Operating temperature: from 20 °C to -80 °C

- Versions for classified or secured areas available

- Compliance with key international design and construction principles (PED - GMP - ASME - ANSI, etc.)

- Multidisciplinary design processes (mechanical, electrical, and instrumental) in both the preliminary design phase and the execution phase

- Project management, supplier control, and testing during installation

Multipurpose Monoblock Cooling Units

For over 80 years, Angelantoni has been developing and building a variety of refrigeration systems, especially for applications in the chemical and pharmaceutical industries. Our team of experts with extensive experience in the planning and delivery of refrigeration systems serves both Italian and international customers.

Our expertise lies in the standardized production of monoblock brine cooling units (water-ethylene or NaCl2-glycol mixture) down to -30 °C. Standard cooling units are also available in versions for temperatures down to -50 °C with two-stage compressors or screw compressors using suitable brine fluids.

All systems are equipped with automatic control and monitoring systems for operating conditions. Alarm systems can be redundantly configured to meet the strictest reliability requirements. Alarms triggered by the system can be transmitted to the control center via SMS or email.

Give Us a Call

and we'll discuss your requirements, costs, and everything you'd like to know in an informal, non-binding conversation.

Why not call now?

0721 - 62 69 08 50