- Home

- en

- datalogger-monitoring-systems

- msr-applications

- performance

- climatic-measurements-in-trams

The use of MSR mini data loggers can help to save energy

Author: Sven Strebel, Research Associate in the Renewable Energies Research Group, Zurich University of Applied Sciences.

Whether bus, streetcar or train: if the temperature in the passenger compartment is reduced by a few degrees, heating costs in local public transport can be cut considerably. To prove this scientifically, the University of Applied Sciences in Rapperswil is determining the electrical energy required to heat the passenger compartment - with the help of small MSR385WD wireless data loggers.

Electric railroads can save electricity - both through energy-efficient vehicles and systems (e.g. track systems, safety systems, stations) and through innovative operation with modern traction systems. The modernization of the vehicle fleet, the recovery of braking energy and energy-saving driving styles reduce electricity consumption. While efficiency increases have been achieved in traction power in recent years, this savings potential for the provision of space heating, particularly for existing vehicle fleets, has not yet been exhausted.

Great savings potential in local electric public transport

In local public transport, passengers are only in the vehicle for a relatively short period of time, so it can be assumed that clothing adapted to the weather will not be removed. Large temperature differences between inside and outside can therefore have a negative effect on thermal comfort and cause a correspondingly high energy requirement. This is particularly the case when electrically powered public transport vehicles use conventional resistance heaters to provide the necessary room heating, which have not been used in buildings and homes (electric "night storage heaters") for some time for reasons of efficiency. Due to their relatively compact design, public transport vehicles also have a relatively poor insulation value compared to buildings, which means that high heat outputs are required to heat the passenger compartment.

By lowering the interior temperature in streetcars, it may be possible to achieve energy savings without a major loss of comfort - again due to the short length of stay. This is crucial, as various studies have shown that the energy required to heat electric vehicles accounts for between 10 and 50 percent of the total energy requirement.

As part of a master's thesis for the MSE (Master of Sciences in Engineering) course at the University of Applied Sciences in Rapperswil, the specific heating energy requirement of a "Cobra streetcar" operated by the Zurich public transport company in winter was investigated. For this purpose, the electrical energy requirement for heating the passenger compartment, the solar heat input through the windows, the passenger and equipment waste heat and the temperature difference between the passenger compartment and the surroundings were investigated during regular streetcar operation

Data logger with wireless sensors for wireless climate measurements

However, a compromise had to be found for the interior temperature measurement in order to measure the air temperature of the relevant zones (seating and standing area) on the one hand and to install the sensors in such a way that they cannot be manipulated or removed during operation on the other. Furthermore, the different areas inside the streetcar (foot and head area, near the doors, etc.) and the five parts of the vehicle must be taken into account, so that the measuring points must be distributed over the entire vehicle.

Small sensor modules and data loggers, which have already proven themselves in many different applications in the industrial, transportation, logistics and machinery sectors, have made a significant contribution to the measurements required for this.

The small size of the temperature sensor module, the sufficiently long autonomous operating time with the built-in battery and the simple configuration and monitoring of the measured values using the cloud solution from MSR were ultimately the decisive criteria that spoke in favor of this company's complete system.

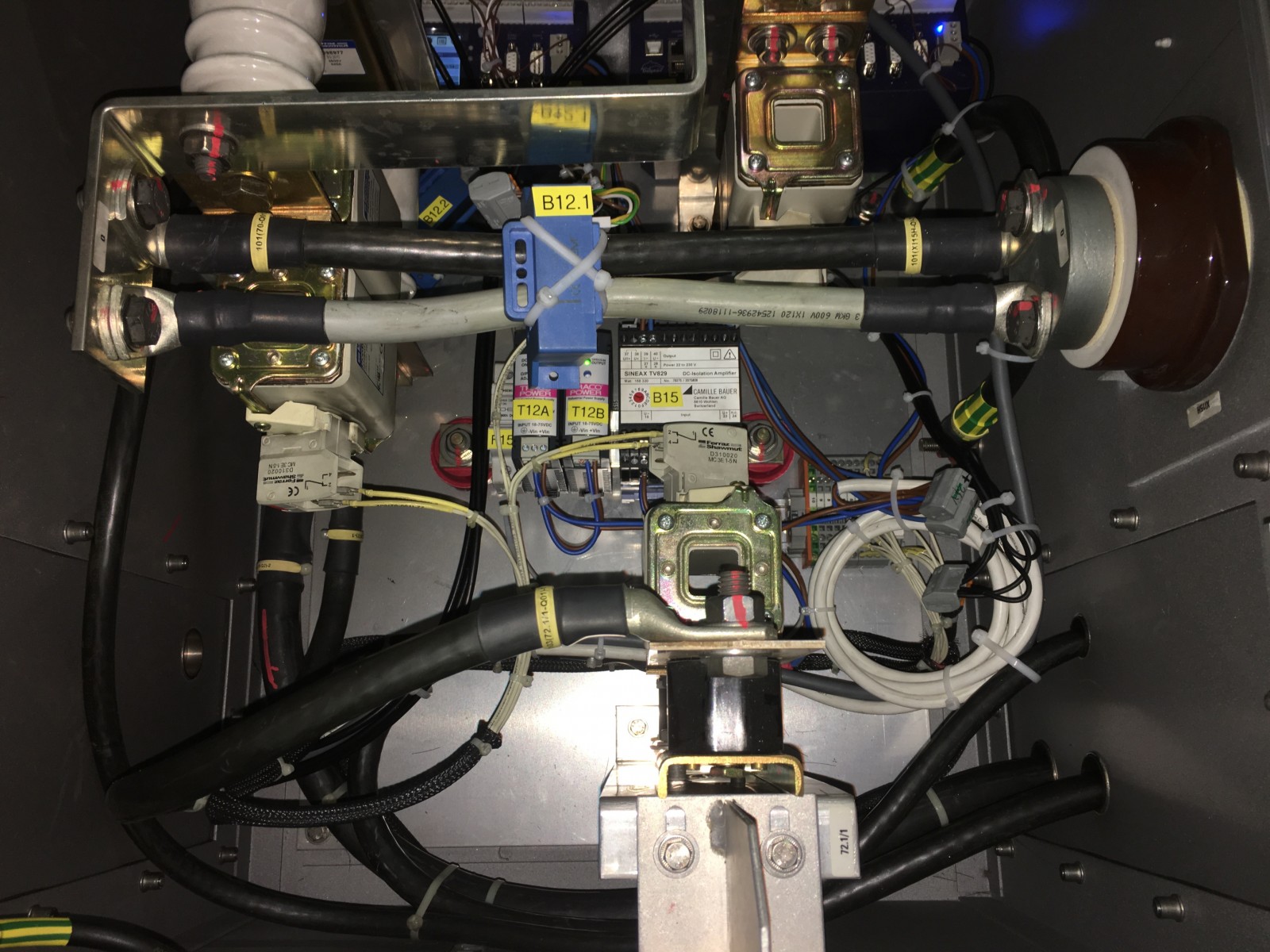

As wiring traditional temperature sensors inside the vehicle would have been very difficult to implement, the company's MSR385SM wireless temperature sensors with transmitter module and an MSR385WD series wireless data logger were used. A total of 20 sensors were distributed throughout the vehicle, with the central wireless data logger installed in the middle of the streetcar, and the data was uploaded to the MSR cloud via its mobile router. The sensors were self-sufficiently powered by batteries. In addition to the measurement technology, an air temperature sensor and several solar radiation sensors were also installed on the roof of the vehicle to record the outside temperature and the solar radiation hitting the window surfaces.

From the sensor module to the cloud

With the MSR385WD wireless data logger, temperature, humidity and pressure can be permanently recorded at various measuring points and at operating temperatures from -20 °C to +125 °C and monitored regardless of location - features that make the logger very well suited to the task in the streetcar. The data logger has an integrated 868 MHz ISM band receiver module, which it uses to receive and store data from up to ten MSR385SM sensor transmitter modules. These transmitter modules use sensors to record temperature curves, humidity and pressure and send the measured values to the data logger in the license-free ISM band. Depending on the frequency of measurements and radio transmissions, the power supply for the transmitter modules is guaranteed for up to five years. Due to their heat resistance, the transmitter modules, depending on the housing type, allow measurement applications even at high operating temperatures of up to +125 °C - although this was not required here. The measuring and transmission intervals of the transmitter modules can be set as follows: 1 s, 10 s, 1 min, 15 min, 1 h.

Depending on the selected housing type, the transmitter modules are powered by a rechargeable 260 mAh Li-Po battery or an 800 mAh Li-SOCl2 battery. Optimized power management ensures that the power supply of the mini transmitter modules is guaranteed for up to five years, depending on the frequency of measurements and radio transmissions. The smallest housing version of this compact transmitter module weighs approx. 25 grams and has external dimensions of just 35 x 55 x 25 mm, allowing it to be placed in inaccessible locations, as shown here. An integrated flash memory ensures data security in the event of a power failure.

The measured value curves of these transmitter modules recorded by the data logger can be read out via a USB interface and further processed with the MSR PC software for data analysis. In addition, a GSM module allows the MSR385WD to be connected to the "MSR SmartCloud", the web-based service for location-independent data monitoring. The wireless data logger is also equipped with a color OLED display for the direct display of data. The high display quality makes it easy to read measured values even in complete darkness and from practically any viewing angle.

Meaningful results

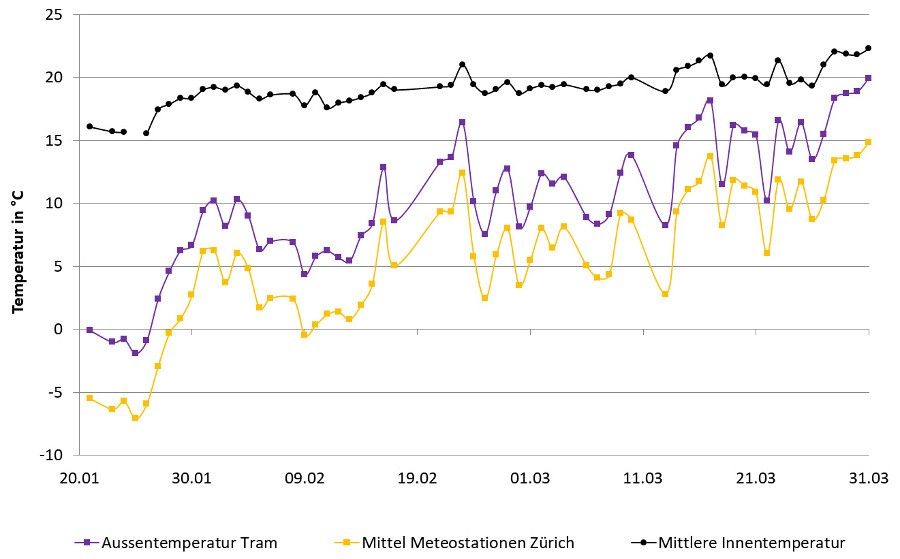

The main aim of the measurements was to identify potential energy savings. In this context, the graph shown here shows the course of the internal streetcar temperature recorded by the sensors and loggers, the external air temperature and the average air temperature over the urban area of Zurich over the investigation period of more than two months.

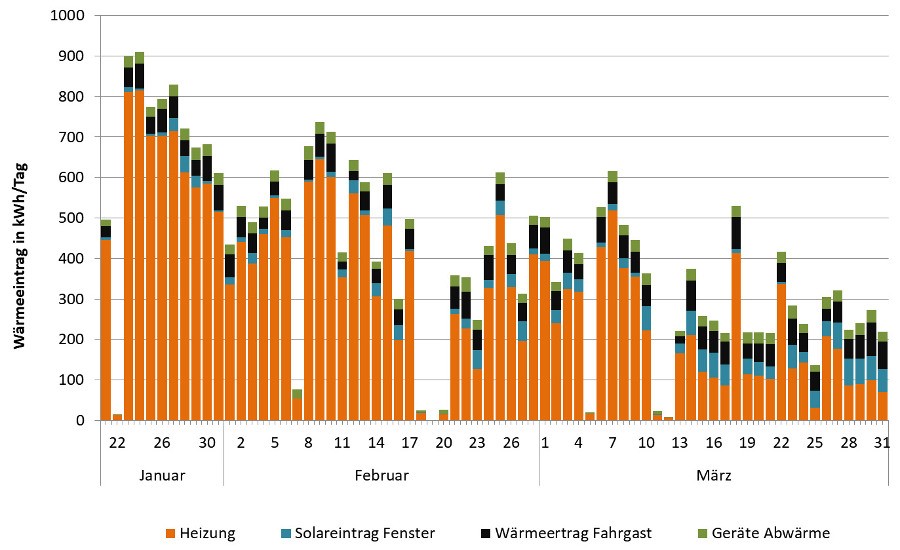

A further graph also shows the heat input from the various heat sources (heating, solar input from windows, etc.) per day during the study period. It should be noted that the data is not standardized and varies according to the duration of streetcar use on the day in question. On days with a very low heat input (< 50 kWh/day), the vehicle is not in regular use. The diagram shows that the vast majority of the heat input is generated by the electric heating and amounts to between 100 and 800 kWh per day and streetcar, depending on streetcar use and ambient temperature. By way of comparison, the average electrical energy requirement of a typical 2-person household is around 4500 kWh per year.

Based on these climate measurements, the annual heating energy requirement for a Cobra streetcar can be estimated at around 72 MWh. Lowering the interior temperature by 2 degrees Celsius would already result in savings of around 25 percent. Assuming that the entire electrically powered vehicle fleet of the Zurich public transport company has the same specific heating energy requirement, this would result in annual savings of around 3.3 GWh. This corresponds to the electrical energy requirements of around 730 single-family homes. In contrast to other measures such as optimizing insulation or installing more efficient heating appliances, lowering the interior temperature is a relatively simple measure from a technical and financial point of view to reduce energy requirements.