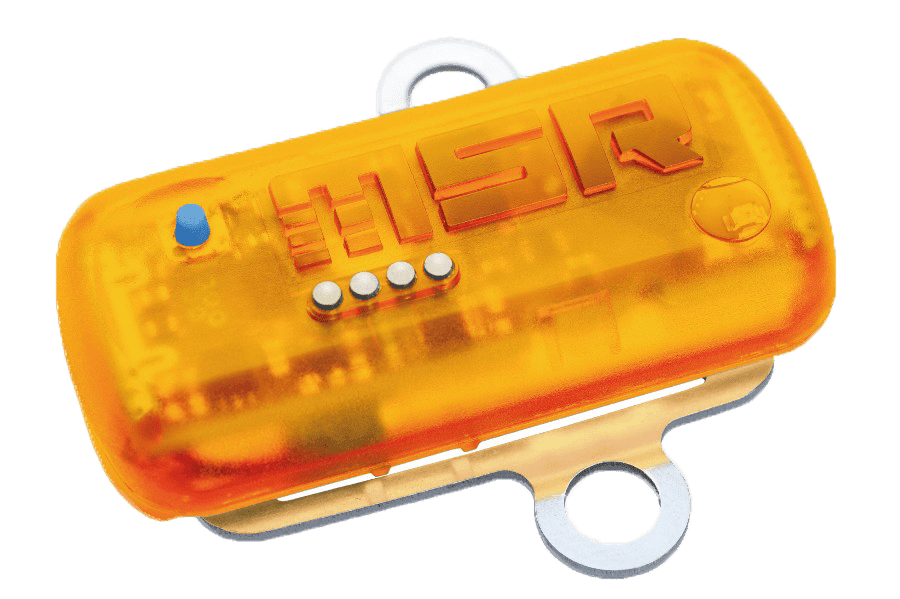

The transport logger for shock - MSR175

The self-sufficient shock data logger MSR175 uses high-resolution shock sensors to seamlessly record what happens to your goods during transportation. The logger data can then be analyzed very precisely with the intuitive MSR Shockviewer software - whether for damage assessment or to improve transport packaging.

Cost-effective transport logger

Two 3-axis acceleration sensors (±15 g and ±200 g)

Measuring rate of up to 6,400 / second

Memory capacity of 2 million measured values

Includes temperature sensor, optional humidity, air pressure and light

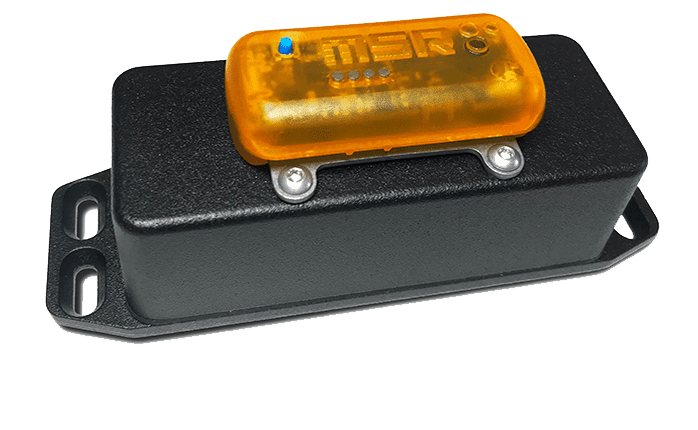

MSR175 with Li-Po battery

Transport monitoring, documentation of transport damage

Be it for proof in liability matters, for early detection of transport damage or for optimizing packaging: The MSR175 shock data logger uses sensors to precisely record critical transport events such as shocks, impacts or temperature fluctuations and provides clarity with objective measurement data.

- +

Exceptionally high measurement rate for shock measurements

Get an accurate picture of shock events and ensure clear facts for proof of causation and damage.

The two 3-axis accelerometers (±15 g and ±200 g) integrated in the MSR175 record critical events such as shocks and impacts at a measurement rate of up to 6,400 measurements per second. This high measuring rate ensures that the logger can also detect very dynamic and short-term impacts, where other loggers with a lower measuring rate can only detect such an event by chance. - +

Best price/performance ratio

The MSR175 is not the cheapest solution on the market, but it is the best value for money.

You will find cheaper and similarly small data loggers for shock monitoring on the market, but these do not come close to the performance of the MSR175. The MSR175 is superior to other products due to its high sampling rate, high storage capacity and accuracy in a very compact format. The fact that the data logger has two integrated 3-axis acceleration sensors (±15 g and ±200 g) allows you to adjust the data logger optimally to your application. This gives it a level of flexibility that is not possible with many competitor products. When deciding on a logger, it is often not clear whether 15 g is sufficient or whether 200 g would be better for the application in question. With the MSR175, both options are available.

The additional temperature, humidity, pressure and light sensors ensure that it covers the most important physical measured variables with one logger. In addition to excellent customer service, you also benefit from the high reliability and durability of the data logger, which is manufactured in Switzerland. - +

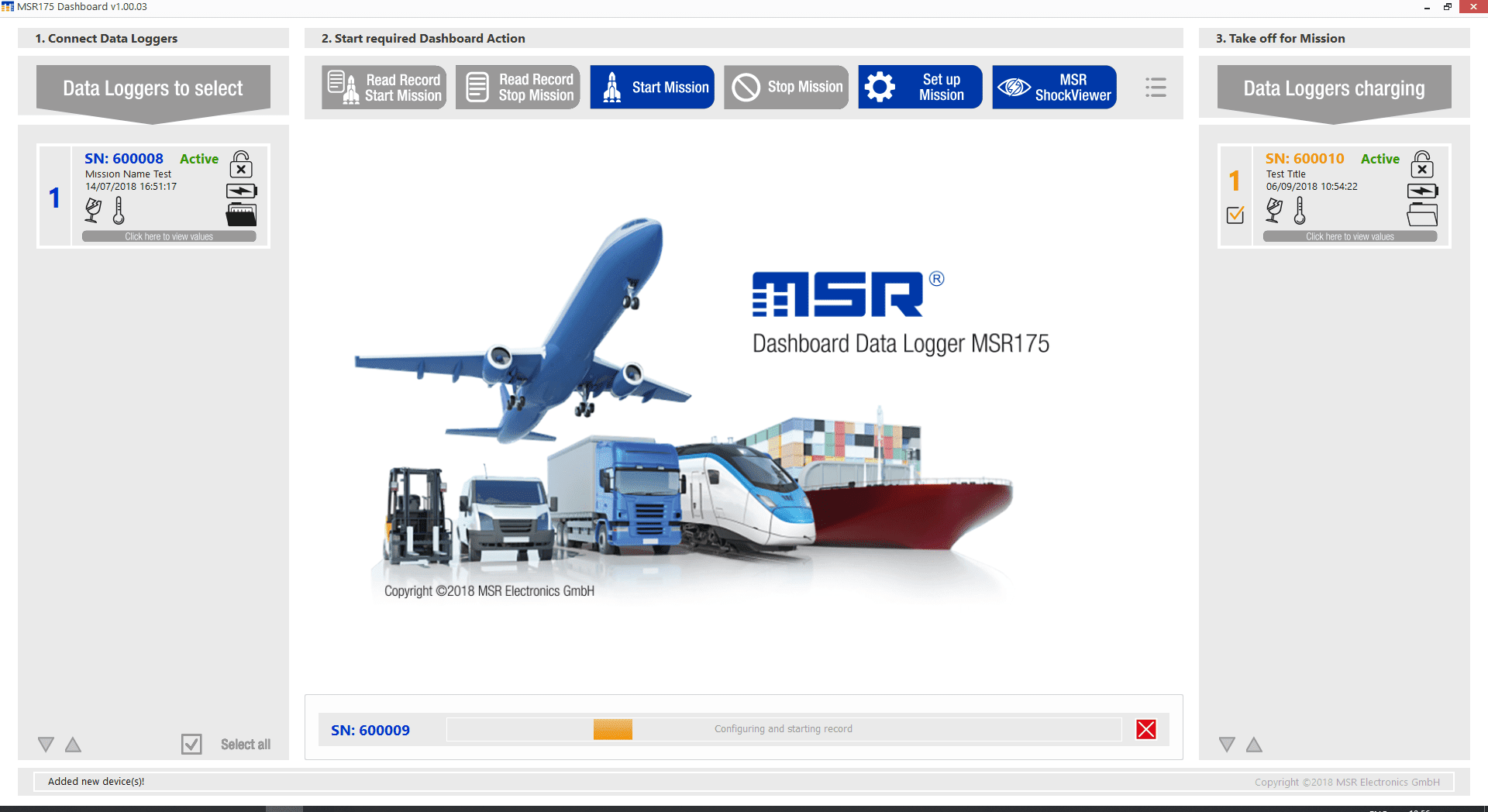

Easy handling, powerful software

You do not need to spend a lot of time training or buy expensive software to use the MSR175.

In contrast to some competitor products, the powerful PC software is included with the MSR175. With the MSR175 dashboard software, configuring the MSR175 and reading out the measurement data via USB is child's play. To create an automatic report, simply click on the MSR ReportGenerator included in the software package. And the basic version of the MSR ShockViewer analysis software is available to the customer for detailed evaluations.

Powerful software for shock monitoring

Our specialized software for shock data loggers makes it easy to configure and evaluate shock data. The MSR ShockViewer allows the user to graphically display and perform advanced data analysis of the shock values recorded by the data logger. The intuitive evaluation software is capable of quickly processing millions of data from dynamic processes - such as critical shock events that can occur during transportation.

Available in four variants

Our shock data loggers with two internal 3-axis accelerometers (±15 g and ±200 g) are available in the following variants:

|

Variant 1 |

with internal temperature sensor |

|

Variant 2 |

with internal temperature, humidity, pressure and light sensor with 230 mAh lithium polymer battery |

|

Variant 3 |

with internal temperature sensor, with Li-SOCI2 battery 3.6 V, 7700 mAh, replaceable, battery life at least 2 years |

|

Variant 4 |

with internal temperature, humidity, pressure and light sensor with Li-SOCI2 battery 3.6 V, 7700 mAh, replaceable, battery life min. 2 years |

MSR175 with Li-SOCI2 battery

Technical information on the sensors

| Measured variable | Measuring range | Measuring accuracy | Measuring/storage rate |

| 3-axis acceleration | ±15 g and ±200 g (-20 to +65 °C) | 15 g sensor: ±0.15 g (0 ... 5 g, +25 °C) ±0.3 g (5 ... 15 g, +25 °C) 200 g sensor: ±2 g (0...15 g, +25 °C) ±5 g (15 ...100 g, +25 °C) ±10 g (100 ...200 g, +25 °C) |

up to 1600/s (±15 %) up to 3,200/s (±15 %) up to 6,400/s (±15 %) |

| Temperature range | -20 to +65 °C | ±0.5 °C (-10 ...+65 °C) | every 10 min. |

| Relative humidity | 0 to 100 % rel. humidity (-20 to +65 °C) |

±2 % rel. humidity (10 to 85 %, 0 to +40 °C) ±4 % rel. humidity (85 to 95 %, 0 to +40 °C) |

every 10 min. |

| Air pressure | 0 to 2000 mbar absolute (-20 to +65 °C) |

±2.5 mbar (750 to 1100 mbar absolute, +25 °C) |

every 10 min. |

| Light | 0 to 83'000 lx | max. sensitivity at 550 nm | every 10 min. |

General technical data

| Housing | Variants 1 and 2: PC design housing, encapsulated IP67 Variants 3 and 4: PC design housing, encapsulated IP65 |

| Dimensions & weight | Variants 1 and 2: 47 x 16 x 54 mm (W x H x L), approx. 28 g Variants 3 and 4: 49 x 39 x 122 mm (W x H x L), approx. 180 g |

| Memory capacity | over 2,000,000 measured values |

| Medium | air |

| color | Amber |

| Button | Start measurement/query status |

| Power supply | Optionally either 230 mAh lithium polymer battery, rechargeable via USB port, recording time up to 8 weeks, or replaceable Li-SOCI2 battery (3.6 V, 7700 mAh), battery life at least 2 years |

| options | Charging station (USB hub) for 7 MSR175 (article number B47002) |

| Interface | USB INTERFACE |

| PC software | Free MSR ShockViewer basic version MSR ShockViewer Pro version for a fee (available at a later date) |

| Operating conditions: Temperature |

-20 to +65 °C |

| Optimum storage conditions: Temperature Humidity |

+5 °C to +45 °C (ideal storage conditions for battery) 10 to 95 % relative humidity, non-condensing |

| Standards | The MSR175 complies with the EU RoHS / WEEE directive. |

What is a shock data logger?

A shock data logger or vibration data logger is a measuring instrument that is able to independently record shocks or vibrations over a certain period of time. The digital data is usually available in the form of acceleration and time. The shock and vibration data can be retrieved (or transmitted), viewed and analyzed after recording.

Unlike a shock data logger, a shock indicator is used to show whether or not the threshold value of a particular shock has been reached.

How does a shock logger work?

A logger consists of sensors such as accelerometers, storage media, a processor and a power supply. The sensors measure and store shocks either as an entire waveform, as summarized data or as an indication of whether a threshold has been met. Some devices have built-in accelerometers, while others can use external accelerometers.

The processor processes the measurement data and stores it on the storage medium together with the associated measurement times. This means that the measurement data can be retrieved after the measurements have been completed, either directly on the logger or via an interface to a computer. Software is used to display the measurement data in the form of tables or graphs and provides functions for evaluating the measurement data. The shock and vibration data is recorded either continuously over a defined period of time or event-controlled, whereby the recording of the data is determined by certain criteria. With such an event-driven measurement method, certain shocks that exceed a critical duration or strength can be recorded. Some have wireless features such as Bluetooth transmissions to smartphones.

Shock loggers usually use non-volatile storage media to record the measurement data. These can be hard disks or EEPROMs, for example. Such devices do not lose the data when the device is switched off. This also means that the measurement data remains stored in the event of a power failure.

Navigation

Produkte

Branchen & Anwendungen