- Home

- en

- datalogger-monitoring-systems

- msr

- vibration-datalogger

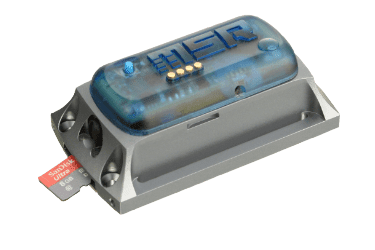

Data logger with vibration sensor

Vibration measurement plays a crucial role in various industries, as vibrations can have a significant impact on the productivity, reliability and safety of machines and structures. By recording and analyzing vibration data, potential problems can be detected early and appropriate action can be taken to prevent costly breakdowns or damage. With our data loggers, you can record and precisely analyze vibrations at high speed.

Record vibrations with data loggers

Our high-quality MSR data loggers enable the precise acquisition and recording of vibration data for a wide range of applications. Whether machine monitoring, structural monitoring or quality assurance - our vibration data loggers offer you the required accuracy and reliability.

The high-quality acceleration and vibration sensors record the measurement data on an internal memory and allow you to subsequently evaluate it using free analysis software.

Features of our vibration data loggers:

- High measurement accuracy for precise vibration measurements

- Wide frequency range for recording different types of vibration

- Compatibility with various sensors for versatile applications

- Large memory capacity for long-term data recording

- Customizable sampling rate for different requirements

- Robust housing and reliable power supply for use in demanding conditions

- Easy configuration and operation for straightforward handling

- Data transmission and analysis for efficient data processing and visualization

- Compact size and portability for use in different locations

What are the benefits of measuring vibration?

Detect faults at an early stage

By continuously recording vibrations, potential problems can be detected at an early stage. Deviations from normal vibration patterns can indicate impending faults or damage. In this way, suitable measures can be taken in good time to avoid costly failures or major damage.

Diagnosis and troubleshooting

Recording vibrations provides valuable data for diagnosing and rectifying problems. By analyzing the vibration data in detail, the causes of unusual vibrations or oscillations can be determined. This enables targeted identification of faults or defects and supports effective troubleshooting.

Monitor conditions

Recording vibrations enables continuous condition monitoring of machines, systems or structures. Trends and changes in condition can be identified through regular analysis of the vibration data. This enables preventive maintenance and optimized maintenance plans to improve the service life and reliability of the monitored systems.

Increasing performance

The recording and analysis of vibrations enables the optimization of processes and performance. By understanding the vibration characteristics, targeted improvements can be made, for example to increase the efficiency, accuracy or stability of machines and systems. This can lead to higher productivity, quality improvements and cost savings.

Areas of application and case studies of our vibration measuring devices

FAQ about vibration measurement

- +

What is a vibration measuring device called?

A vibration measuring device is referred to as a vibration meter or vibration measuring device. It is used to measure and quantify the intensity, frequency and other parameters of vibrations. A vibration meter can use various sensors, such as accelerometers or velocity sensors, to measure the vibrations. It can also provide other functions such as data logging, analysis and reporting to enable a comprehensive assessment of vibrations. Vibration meters are used in various industries and applications, including engineering, construction, automotive, aerospace, environmental monitoring and many others to measure and monitor vibration exposure. - +

In which measurand is vibration specified?

The measurand in which vibration is specified is frequency. The frequency indicates how often a vibration is repeated per unit of time and is measured in Hertz (Hz). It is directly related to the number of vibration cycles per second. The higher the frequency, the faster the object or structure vibrates.

The frequency of a vibration is a crucial parameter that provides information about the type of vibration. Vibrations can have different frequency ranges, such as low-frequency (0.1 Hz - 10 Hz) for slow vibrations or high-frequency (10 Hz - 10,000 Hz and above) for fast vibrations. The frequency specification is important in order to take the correct measures to monitor, analyze and control vibrations.

In addition to frequency, amplitude, which indicates the strength or intensity of the vibration, may also be relevant. It is usually measured in units such as meters (m) or millimeters (mm) and represents the maximum deflection or displacement during vibration. Amplitude and frequency are important parameters for characterizing vibrations and taking appropriate measures.

- +

How can vibration be measured?

Acceleration sensors

These sensors, also known as accelerometers, measure the acceleration experienced by a structure or machine. They record the vibrations in the form of acceleration values.Velocity sensors

These sensors, also known as velometers, measure the speed at which a structure or machine is moving. They provide information about the speed of the vibration and record the vibration speed.

Displacement sensors

These sensors, also known as strain gauges, measure the relative displacement or movement of a structure or machine. They detect changes in position or deflection and provide information about the displacement caused by vibrations.

Microphones

Microphones are normally used to detect sound waves, but can also be used to indirectly measure vibrations. They react to the sound waves generated by vibrations and can provide information about the intensity and frequency of the vibration.

Laser vibrometer: A laser vibrometer uses a laser beam to measure the vibrations of a surface without contact. It detects the displacement or movement of a surface by measuring the phase shift of the reflected laser beam.These methods for detecting and measuring vibrations can vary in suitability depending on the application, accuracy requirements and cost. Choosing the right detection method depends on the specific requirements and objectives of the vibration analysis.

Contact us for a no-obligation consultation! - +

How does vibration recording with data loggers work

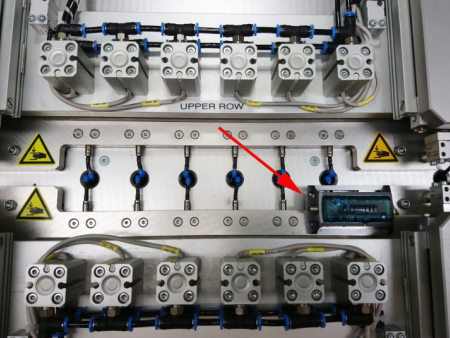

Sensors: Our data loggers are equipped with high-quality vibration sensors that enable precise measurements of vibrations. These sensors record the acceleration, speed or displacement of the vibrations and convert them into electrical signals.

Data recording: The data loggers record the vibration data continuously or at set intervals. They have internal memory or can use external storage media to record a large amount of data.

Configuration and control: Our data loggers offer user-friendly interfaces and software that allow you to configure the acquisition parameters such as sampling rate, sensitivity and recording duration. They also enable remote monitoring and control of data acquisition.

Data analysis: After acquisition, you can analyze the collected vibration data on your preferred analysis platforms. You can use various analysis techniques such as FFT (Fast Fourier Transform) to create frequency spectra and identify specific vibration characteristics.

Reporting: Our data loggers allow you to generate reports with the vibration data collected. These reports are used for documentation, fault diagnosis, quality assurance and to support decision-making processes.

By accurately capturing, recording and analyzing vibration data, our data loggers provide an effective solution for monitoring vibration in various applications. Find out more about how our data loggers work and how they can help you gain valuable insights and make informed decisions. Contact us now for more information!