- Home

- en

- datalogger-monitoring-systems

- datatrace-applications

- lyophilization-process

Validation of the lyophilization process

How can I validate my lyophilization process?

Lyophilization is a freeze-drying process in which the product is exposed to a very cold ambient temperature and kept under vacuum. During this process, it is important that the temperature-controlled shelves bring the product to the correct temperature. This is normally achieved via a stainless steel shelf of a specific size, which can be heated from below. Heat is then applied to the product in a frozen state under vacuum conditions; the water contained in the product sublimates from a solid to a gaseous state without compromising the integrity of the product. For this reason, not only the temperature of the shelf, but also that of the product should be closely monitored. Validating the freeze-drying process in this way guarantees its efficiency.

Micro Flex data logger for the validation of lyophilization processes

Validation with real-time data

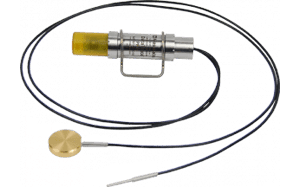

Normally thermocouples would be used to validate the freeze drying process, but we realized that a more practical solution was needed and developed the NEW Micro Flex data logger! The Micro Flex Logger is equipped with a small probe that can be inserted directly into ampoules and vials for temperature monitoring. A special surface attachment (puck) is supplied as an accessory. The probe is inserted into the puck and can then be used directly for surface measurement in the freeze-drying process. These new products provide you with a complete sensor set for monitoring your product in a convenient way, so that you can determine both surface temperature and ampoule temperature directly.

Similar to thermocouples, the Micro Flex Logger also reacts ideally to temperature fluctuations. The puck used for the Micro Flex Logger is made of brass, which has an excellent temperature response time. Because the Micro Flex Logger is built on the foundation of our MPRF product line, you can easily access real-time data directly during the process. Now you can spontaneously make changes or decisions based on concrete data instead of following your gut intuition. You no longer have to make assumptions, you know exactly which parameters to change while the process is still running. Feel confident in validating your process and save time. When you monitor a process remotely, you can immediately see if a problem needs to be addressed immediately based on real-time data.

How does it all work?

To perform a validation with the Micro Flex data logger, first place surface probes in the locations you suspect are the coldest. Then insert a probe into a vial and make sure it reaches the correct temperature in the specified time. This is a typical validation process, with the difference that you now have the right tool to do this efficiently with the Micro Flex Logger and surface probes.

Don't forget to also perform a spatial temperature profile of your shelf. Use a systematic approach by placing all loggers at regular intervals on the shelf, with probes in all corners and in the middle. You will need to decide how many sensors are needed to achieve the best possible result.

Click here to find out more about the Micro Flex data logger. If you have any questions about the new Micro Flex Logger or the surface probe, or need assistance with the next validation or mapping of your freeze-drying process, please contact us!