Choosing a conductivity logger

The importance of good water quality cannot be overstated. It is essential not only for the health of the general population but also for the network of ecosystems that it supports. Surface and groundwater contamination is of great concern for biologists, environmental scientists, researchers, and water quality managers who assess the effects of natural and synthetic pollutants on water supplies. Conductivity loggers are ideal for monitoring the impact on water resources from pollutants such as road salt, and agricultural and highway runoff.

Conductivity, or the measure of water’s ability to carry an electrical current, is affected by the presence of pollutants or salts. The purer the water, the lower the conductivity will be. Continuous monitoring of conductivity at multiple sites along a stream or in a well will determine when and where spikes of high conductivity occur, with the goal of identifying the sources of contamination that caused the high conductivity. Conductivity can also be used to monitor the salinity of water. Salinity is an important factor in the health of aquatic ecosystems, and for coastal and estuary research. The most common way to obtain salinity changes over time is to log the conductivity and temperature, and then use the Practical Salinity Scale 1978 (PSS-78) equation to convert this to salinity in Practical Salinity Units (PSUs), an accepted approximation of parts per thousand (ppt). Most conductivity data loggers come with software that can perform this conversion to salinity. Conductivity loggers incorporate a built-in microprocessor, sensor, and battery in a rugged enclosure designed for long-term underwater deployment. They can be deployed and left unattended for days, weeks, or months at a time, collecting data at user-defined intervals and storing it digitally into logger memory. By operating in a continuous monitoring mode, conductivity loggers eliminate many of the hassles of manual data collection approaches and facilitate simultaneous monitoring of multiple locations. Whether you are selecting a conductivity logger for the first time or have experience measuring conductivity, this paper can help you determine the type of logger that best suits your needs. It highlights the five most important considerations in selecting and deploying a conductivity logger:

1. Measurement range and accuracy

2. Other factors that affect accuracy

3. Ease of deployment and offload

4. Software capabilities

5. Cost of ownership

1. Measurement range and accuracy

The first thing you need to determine is that the conductivity logger’s measurement range will cover the range of conductivity or salinity at your site and that the accuracy is sufficient in that range.- If you are primarily looking to track the occurrence of runoff or upwelling events, accuracy may not be as critical, as long as you can see when the changes occurred. On the other hand, it may be important to know the maximum conductivity or salinity levels during these events, in which case the accuracy of these measurements is significant.

- Tidal estuaries can have an especially wide range, going from freshwater to mostly saltwater.

- Note that conductivity is dependent on temperature, so be sure to look at the conductivity/salinity range for the range of water temperatures you expect. For example, the salinity measurement range is typically wider for colder water temperatures.

2. Other factors that affect accuracy

The accuracy of a conductivity logger is highly dependent on how it is designed to deal with the elements in the environment. Unlike other types of data loggers where absolute accuracy is more easily achieved, conductivity loggers must be able to offset the effects of drift and fouling from algae or sediment buildup on the sensor. How the logger handles these issues is just as important as absolute accuracy. Some questions to ask the manufacturer are:- How prone is the sensor to drift?

There are basically two types of conductivity sensors: non-contact sensors and electrode-based sensors. Most conductivity loggers have electrode-based sensors. Generally, electrode-based sensors are more likely to drift than non-contact sensors because the characteristics of electrodes can change, especially in saltwater. - Does the logger software include compensation for measurement drift from fouling?

Fouling, or the buildup of residue or algae on sensors in a water environment, is an unavoidable reality. This fouling can change conductivity measurements, causing measurement drift. Software with drift compensation allows you to enter a calibration value for both the launch time and the readout time, which accounts for drift over the duration of the entire deployment, rather than the launch time alone, resulting in more accurate data. - How easy is it to clean the sensor of any fouling?

Bio-fouling and excessive marine growth on the logger can compromise accuracy, which means you will need to periodically clean the logger sensor. Conductivity loggers with easily accessible sensors that can be cleaned quickly with a cotton swab are easier to maintain than loggers with sensors obscured behind housing features.

- What are the logger’s temperature accuracy and response time?

Look for a logger with an accuracy of at least 0.1°C and a fast temperature-response time, as precise temperature readings are critical to accurate conductivity measurements. If the logger temperature reading is not accurate or has a slow response time, this will result in inaccurate specific conductance readings. For every degree that the temperature is off, the specific conductance reading will be off by 2%. If the response time is slow, then the conductance readings will be erroneous due to thermal lag, the difference between the actual temperature and the current logger temperature reading. Just as important as the response time is that the temperature is measured at the point of the conductivity sensor itself and not at another point inside the logger housing. This ensures that the measurement is truly the temperature of the water and not the temperature within the logger body, which can have a thermal lag and, as a result, a different temperature.

3. Ease of deployment and offload

As with all loggers, an important factor when selecting a conductivity logger is how easy it will be to deploy and then subsequently retrieve the data. Specifically, consider the following:- The conductivity logger should be designed to sink, rather than float, so that it reaches the correct depth for the deployment. Some conductivity sensors require that you add weights to make them sink.

- There should be a simple solution for mounting the logger. An eyelet built within the logger body provides an easy way to hang the logger in a well or attach it to a mounting pole or pipe.

- The smaller the logger, the easier it is to mount and transport to the site. Compact loggers can be deployed in a variety of locations, such as small wells, and are easily hidden and better protected.

- You will need access to the sensor for cleaning and to prevent bubbles from forming. A logger designed for open access to the sensor allows for easier cleaning and better water flow, which in turn provides faster response time and a reduction of air bubbles.

- A data shuttle option provides a convenient way to offload data. Loggers generally provide a way to offload directly to a computer, but this means you either have to bring a laptop to the field or you need to remove the logger from the deployment site and bring it back to the office. With a waterproof data shuttle, you can bring it to the field, quickly connect it to the logger, offload the data, and re-launch the logger right away. You can leave the logger at the deployment site and bring the shuttle back to the office instead.

- When you do want to connect the logger directly to a computer, you’ll want it to connect via a USB port, which allows you to offload data more quickly than a logger requiring a serial port. In addition, loggers that rely on mechanical plug-in connectors can be damaged by water in the field and cause failures. A conductivity logger with an optical interface that is sealed within the logger housing eliminates the possibility of water-related damage and/or failures.

Deployment Best Practice

Once you have selected a conductivity logger, there are several things to consider regarding the actual deployment:- You should have a field calibration meter to periodically take calibration readings.

- The logger should be placed in a location that has good continuous water flow, if possible. Use a PVC pipe with holes to protect the logger in high-flow environments.

- You will need to mount the logger so that the sensor will shed air bubbles, as air bubbles on a sensor can cause significant measurement error.

- Keep the logger at least an inch from metal surfaces. The distance becomes more important the lower the conductivity is.

- Mount the logger in such a way that you can obtain access to the sensor for cleaning with a cotton swab and mild detergent whenever possible – particularly in fouling environments.

4. Software capabilities

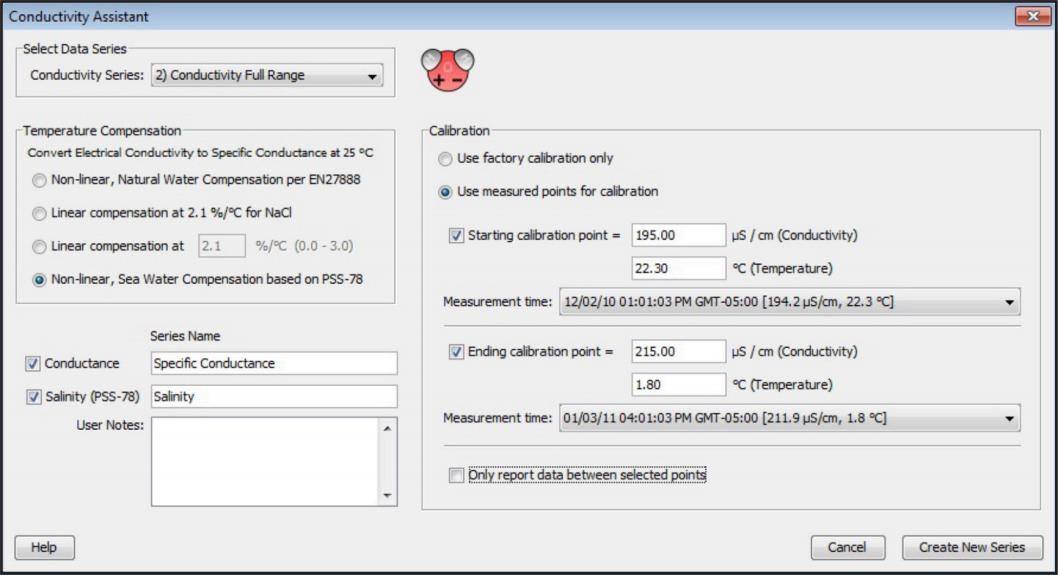

When considering which conductivity logger is best for you, it is also important to evaluate the software that accompanies it. The software, in general, should be highly intuitive so that you can quickly become proficient in configuring parameters, launching the logger, and offloading data. There are several specific features that you should look for in a software package:- Conversion capability – The software should be able to easily convert conductivity data to specific conductance at 25°C and/or salinity. It should also provide a range of options for entering your own coefficients and provide the EN 27888 and ISO 7888 standard conversions for natural water.

- Calibration point handling – There should be a clear, simple way to enter calibration points gathered at the beginning of the launch and at the end when you offload the data, in order to compensate for measurement drift.

- Multi-logger graphing – Viewing and analyzing data from multiple loggers on a single graph is a very useful feature, whether you want to analyze several loggers from the same area or across multiple sites. The software should be able to combine data from multiple loggers in one plot.

- Easy data export – Conductivity data often needs to be incorporated into other software programs, such as spreadsheets or modelling programs. The software should provide a quick way to export the data and save it in several different file types. You should also be able to copy and paste graph images into other programs for generating reports.

- Project save and recall – The software package should allow you to save any changes you make to the graph, preserving plot setup details for future use. While the ability to save your project seems like a basic feature, some software packages do not have this capability.

5. Cost of ownership

As with any purchase, an important consideration is how much will the logger cost. Conductivity loggers are becoming increasingly less expensive, with some below 800€. However, the cost of ownership does not pertain just to the actual purchase price of the logger, but also to its time- and hence money-saving features.- A logger that can compensate for drift means you don't have to go out to the logger and offload data or get calibration readings as often.

- A logger that is easy to clean will also save time, as will a logger build with durable materials that can stand up to the elements and not need to be replaced

- If you can offload data with a shuttle, then you save a considerable amount of time that would normally be spent either bringing the laptop to the field or taking the logger back to the office and then redeploying later.

Conclusion:

- As the demand for water conductivity monitoring grows, so too will the need for instruments that make the process faster, cheaper, and more accurate. Underwater data loggers are the instruments of choice among researchers and resource managers because of their 24/7 operation, high accuracy, ease-of-use, and computer-based analysis and reporting capabilities.