- Home

- en

- datalogger-monitoring-systems

- msr-applications

- human-vibrations

- sports-wheelchair

Product optimization of sports wheelchairs using data analysis

Author: Thomas Brendel, R&D development engineer at Otto Bock Mobility Solutions

The following report was published in the journal Medizin+Elektronik, March 2017.

In order to gain well-founded insights into the intensity of use of an electric wheelchair designed for golf, development engineers at Otto Bock Mobility Solutions GmbH recorded the usage behavior of wheelchair users over a period of several weeks using MSR data loggers.

Mobility is quality of life - this has always been the guiding principle of the German company Otto Bock HealthCare GmbH. With its four business divisions - Prosthetics, Orthotics, Mobility Solutions and MedicalCare - the medical technology company, founded in 1919, is able to offer impaired people a wide range of products and comprehensive services for a more independent and self-determined life. Otto Bock HealthCare GmbH, headquartered in Duderstadt, employs over 6000 people worldwide. In the Mobility Solutions division, Otto Bock engineers develop technical aids for rehabilitation. These can be rehabilitation products such as standing aids and seating systems, but also manual and electric wheelchairs for a wide range of requirements and needs. From robust, flexible folding frame wheelchairs to electric high-tech devices with sophisticated control functions, wheelchairs must meet the highest standards in terms of technology, functionality, individual adaptation, robustness and design.

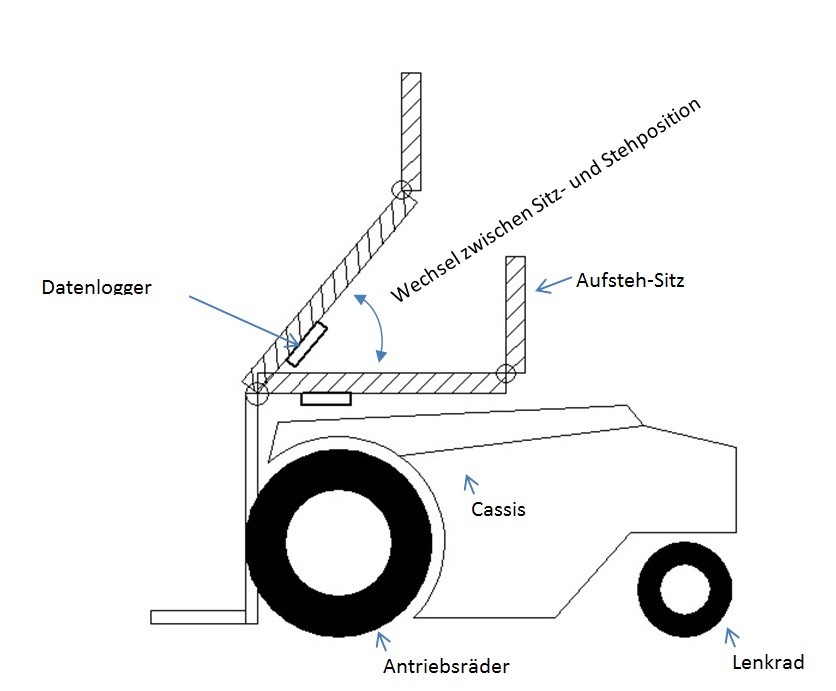

The consistent further development of products with a precise focus on current customer requirements is of central importance to the company's success. The ParaGolfer sports wheelchair is currently the focus of optimization efforts - a successful model for the company. The power wheelchair, which is specifically designed for golf, has a stand-up aid and is constructed in such a way that the user has a secure stance for the tee shot despite walking disabilities. The adjustable seat helps golfers to position themselves optimally in relation to the ball. At the same time, the three-wheel drive configuration meets the special requirements for off-road mobility on the golf course.

Data loggers help to identify weak points

In order to improve a product, you first have to identify possible weak points and analyze their effects. This is why the engineers at Otto Bock used various data loggers to gain in-depth knowledge of the ParaGolfer's product usage. MSR specializes in the development of miniaturized data loggers and has made a name for itself particularly in the field of modular measurement technology. Using sophisticated sensor and processor technology, the compact, autonomous MSR data loggers record a wide range of physical environmental parameters over long periods of time.

In the case of Otto Bock's electric golf wheelchair, the engineers used MSR145 and MSR160 data loggers to investigate how often an average player uses the electric seat stand-up adjustment when tackling an 18-hole golf course and what total number of cycles should be applied to ensure perfect function over the product's service life. To this end, the data loggers recorded the parameters range, speed, frequency of stand-up cycles, power consumption and temperature development. The aim was to be able to design the functional components of the ParaGolfer in such a way that they reliably meet the typical requirements of customers after evaluating the data.

Objective measured values provide clarity

In a field test, the golf wheelchairs of several users were equipped with MSR data loggers and the mechanical-electrical behavior was seamlessly recorded over several weeks. The data loggers were equipped with an internal 3-axis acceleration sensor (±15 g). Sensors connected to the four analog inputs also recorded current, voltage, speed and temperature. The storage capacity of the mini data loggers is two million measured values as standard. This capacity can be increased using a microSD card. This enabled the engineers to record over 1 billion measured values. The USB interface ensured that the respective data logger was supplied with power from the wheelchair's batteries. The signal from the Y-axis of the internal acceleration sensor was stored at a measuring rate of 1 Hz and subsequently evaluated. Special software counted the stand-up events as a change in angle over time as soon as these exceeded a predefined limit value. Over several weeks, the MSR160 data logger also recorded the measured values for current, voltage, speed and temperature at a frequency of 16 Hz. The continuous recording of 16 measurements per second accumulated a very large amount of data. The memory cards therefore had to be read out quite frequently. In principle, the quantity of measured values recorded can be reduced by setting limit values. However, the engineers decided to record all the values first and then extract the relevant data areas later in the analysis. In this way, they could be sure of being able to evaluate all interesting events.

LabVIEW helps with the analysis

Based on the graphical programming environment LabVIEW (Laboratory Virtual Instrumentation Engineering Workbench) from National Instruments, the Otto Bock engineers developed analysis software tailored to the application. Among other things, this analyzes the measured values recorded by the acceleration sensors over time. It calculates the respective seat angle in degrees relative to the horizontal and recognizes events that exceed or fall below a threshold value of 20°. The program marks these events in green in the diagrams so that they can be clearly identified regardless of the zoom factor.

werthzm.n

werthzm.n