- Home

- en

- datalogger-monitoring-systems

- msr-applications

- transport

- foil-test-procedure

Plastic films on the test bench

Authors: Michael Engel, Denis Horn, Dipl.-Phys. Felix Blendinger, Dipl.-Chem. Michael Metzger, Dr. Markus Westerhausen, Prof. Dr. Volker Bucher; Furtwangen University, Rottweil Study Center

Plastic films used in medical products have to meet stringent legal requirements. In addition to biocompatibility, water impermeability is an important criterion. At Furtwangen University, a test stand for measuring water vapour diffusion barriers was set up as part of a project. Reliable temperature and humidity sensors played an important role here - precisely and economically.

Medical devices encompass a wide range of products and procedures that are intended for use on humans. In contrast to drugs, which have a pharmacological, immunological or metabolic effect, the main effect of medical devices is predominantly physical. These include, for example, implants, products for injection or dental products.

Active implantable medical devices occupy a special position. They are inserted into a person's body and remain there. These include pacemakers, infusion pumps or retinal implants, for example, which are subject to the strictest safety requirements. For this reason, active medical devices must be encapsulated with biocompatible materials that are also as impermeable to water vapor as possible in order to avoid complications with electrical components. The article describes a validated test stand for measuring water diffusion barrier layers on flexible plastic films, which are used, among other things, for the external coating of medical devices.

In focus: Properties of the plastic parylene with regard to water vapor permeability

The material to be measured consisted of encapsulated plasma and parylene coatings, among other things, which make the product not only biocompatible but also biostable on the outside. Corresponding films of this material were to be tested. The plastic parylene is versatile, has good mechanical and dielectric properties, a smooth surface, is temperature-stable, chemically inert and solvent-resistant, provides outstanding corrosion protection and is an excellent permeation barrier.

There are devices available to test the properties of this permeation barrier in terms of water vapor permeability, but these are expensive to purchase. It would also be possible to have films tested separately and externally, but this would mean high logistics costs, permanent costs and time expenditure. This dilemma has now been solved by the test stand at Furtwangen University, which uses electronic components, among other things, to test the flexible plastic films mentioned above.

Design of the test stand

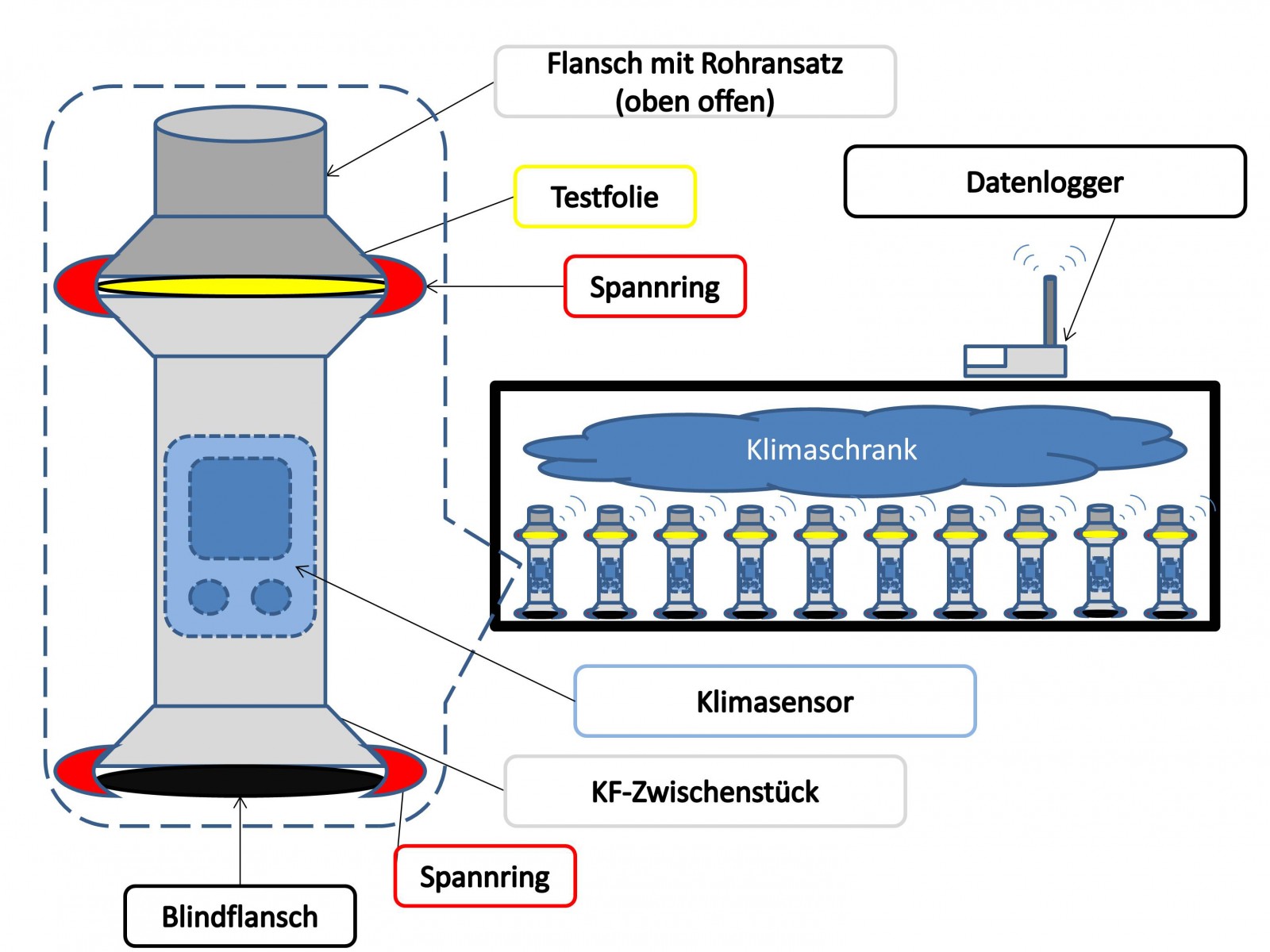

The test stand consists of ten analog measuring units. In general, as shown in the picture, a measuring sensor with an integrated temperature and humidity sensor is installed in a lockable box. This is open on one side so that the film to be tested can be stretched over it. The box is then placed in the climate chamber for several hours or days at a high relative humidity such as 85% and a defined temperature.

Inside the box, measurement data of the current relative humidity and temperature are recorded by the sensor once a minute. Special calibration foils with standardized water vapour permeability can be used to validate the test setup. The internal sensors are MSR385SM modules. They record the values for temperature, relative humidity and air pressure (which is not required in this case) and send the measured values in the license-free 868 MHz ISM radio band to an external MSR385WD data logger.

Monitor data at any time, regardless of location

Advantages of wireless data transmission

The size of the humidity sensor determines which diameter of vacuum tube can be used. And since the sensor transmitter modules work without an external power supply but with their built-in rechargeable battery, there is no need for power supply cables, which could potentially jeopardize the tightness of the components. In addition, data can continue to be recorded even in the event of a power failure. Another advantage is data transmission via radio. This is because wired data transmission would entail the risk that the flange components at the cable feed-through points could become leaky, allowing unwanted water vapor to enter the interior of the measuring arrangement. Another advantage of the sensor modules and data loggers used is their low price, so that the costs for this measuring station could be kept below 5,000 euros.

First, the range of the radio link between the measuring sensor modules and the receiving data logger was tested. In an open space, the range was around 8 m, with a concrete wall in between 5 m, and with the sensors in the climate chamber and the data logger outside the climate chamber approx. 0.5 m. The data logger was therefore placed on the climate chamber when measurements were being taken inside the climate chamber. For continuous monitoring, the receiving data logger was connected to a PC near the climate chamber. The connected data logger could be accessed on a PC via remote access and the data checked.

Conclusion

Navigation

Produkte

Branchen & Anwendungen