- Home

- en

- datalogger-monitoring-systems

- tecnosoft-faq

Tecnosoft - Frequently asked questions

Tip: Use the search function of your browser to highlight search terms! CTRL+F

General

- +

At what temperature/humidity/pressure can I use my logger?

Technical information can be found on the specific data sheet for each device on the cik-solutions.com website. At the bottom of each page is a table with the technical characteristics of each device. - +

Can I use my logger in the X environment (X = special environment, generally different from the one in which the device is normally used)?

For the technical aspects of each data logger, please refer to the relevant pages on the tecnosoft.eu website. If the environment in which you need to use the logger is special and different from the environment for which the logger was designed, please contact Tecnosoft for information. It is necessary to describe the environment in as much detail as possible, e.g.: substances present in the environment, minimum and maximum temperature, minimum and maximum humidity, minimum and maximum pressure, other relevant technical information. - +

Can I use my logger under water/other liquids?

Please refer to the individual device pages on the Tecnosoft.eu website for information on the technical features and use of each device. If a device is specified with protection class IP68, it can be immersed in water. For other types of substances, see the answer to this question. - +

At what temperature/humidity/pressure can I use my logger?

Technical information can be found on the specific data sheet of each device on the cik-solutions.com website. At the bottom of each page is a table with the technical features of each device. - +

Does the sensor measure at the tip of the probe or along the entire length (for loggers with probe)?

The measuring point of the device is located at the tip of the probe, and the temperature is only measured there. - +

Where is the temperature measured (for loggers without tip/probe: SterilDisk)?

The measuring point of the logger is located in the middle of the unlabeled surface and the temperature is only measured there. For surface monitoring, this area must be stuck to the surface; for ambient monitoring, the logger must be positioned with this area facing upwards. - +

How long is the response time (T90) of the sensor?

The response time varies from device to device. The thinner the diameter of the tip, the faster the response time usually is. In general, loggers with a tip have a faster response time than those without, with an internal sensor. - +

What is the response time of the sensor?

The response time is the time it takes for a system to react to a certain input.

When we talk about sensors, we mean the time it takes a sensor that is brought from one environment to a certain environment before it recognizes the new environmental conditions.

For example, a temperature sensor that is brought from room temperature to an environment (say 25°C) with a different temperature, regardless of whether the difference is small or large. The time it takes for the sensor to recognize the new temperature is the response time.

It is usually referred to as T90, i.e. the time it takes the sensor to detect 90% of the temperature difference. A temperature sensor that has been at 0 °C for some time and has therefore stabilized at this temperature is therefore placed in a 100 °C environment. The time it takes to detect 90 °C (90 % of the temperature difference between 0 and 100) is its response time, sometimes T63 is used instead.

However, the temperature difference is not the only variable to consider, as the response time must always be specified in relation to the environmental conditions: in still air, in motion, in still liquid, in motion, what type of liquid, the speed of motion, etc.

In general, sensors with a fast response time are preferred for short processes and especially for frequent temperature changes, such as in a sterilization process. For long processes or with small variations in temperature over time, or in any case very slow, such as monitoring a cold room or a room, temperature sensors with a slower response time can be used. - +

How can I start recording or evaluate measurement data?

The method for starting and downloading data depends on the system you have installed. In general, the system consists of a data logger, interface and software. The interface may also be missing and the data logger may be connected directly to the system that downloads or programs the data. As a rule, all programs have a button to connect to the data logger, after which you can choose whether you want to start it or download its data. - +

Where can I find the serial number of my logger?

The serial number is usually printed, lasered or attached to the data logger itself by means of a label. It can be reproduced in full or in part. Serial numbers can be found on sales and delivery documents, on old certificates or in the software. In the latter case, open the software archive to see which data loggers you have downloaded so far.

Certificates & Calibration

- +

What does it mean that the accuracy is valid in the calibration range?

The data loggers have an operating range, i.e. a range in which the logger can operate in its entirety, an operating range of the sensor, i.e. the range in which only the sensor can operate in its entirety, an operating range of the sensor, i.e. the range in which only the sensor can operate in its entirety i.e. the range in which only the sensor covering the logger (i.e. without electronics and batteries) can operate, and a calibration range, i.e. a range in which the logger is actually calibrated.Regardless of whether the loggers are supplied with a calibration certificate or on request, standard calibrations are performed at fixed points that are the same for all in order to standardize the calibration processes. However, it is possible to request additional points within this standard calibration range and even beyond for some objects: In this case, the calibration range of the logger is extended. The specified accuracy refers only to the calibration range, as the points of the calibration curve are corrected exactly within this range. Only some loggers have good accuracy even outside the calibration range, whereby the accuracy decreases outside the extreme values of the calibration range itself. These loggers are: MicroW S and Pressure Disk.

With other models, the accuracy outside the calibration range is unpredictable. For this reason, it is advisable to check the calibration code when selecting the monitoring system and request additional points if necessary.An example

Take for example the MicroW L. These are its characteristics:

- Operating range: -40 ° C to +140 ° C

- Operating range of the sensor: -40 °C to +220 °C

- Calibration range: 25 °C to +140 °C

This means that the logger can withstand temperatures from -40 °C to 140 °C. The sensor can withstand and read temperatures from -40 °C to 220 °C, but is calibrated in the range from 25 °C to 140 °C. The stated accuracy of +/- 0.1°C applies in the latter range, and if I wanted to use it for monitoring at lower temperatures, for example, I would need additional points (for example 0°C). Apart from the loggers mentioned above (S-MicroW, S-Disk and PressureDisk), all others require an additional point at least every 25/30 °C to achieve good accuracy.

Note: It is possible that the accuracy may be lower than specified due to the extension of the calibration range.

- +

Are all loggers supplied with a certificate?

Many loggers are supplied with an ISO calibration certificate, which is included in the price. For some loggers, however, the certificate is provided on request. - +

How can I obtain a certificate?

If you have a data logger that you would like to recalibrate, simply send it to Tecnosoft and state the reason for the return. After an inspection of the data logger, you will receive a quote for the recalibration of the standard points or any additional point previously specified.- +

What does it mean that the loggers are recalibrated?

This means that the calibration curve of the data loggers as well as the calibration and reading data are brought up to the best possible level after a calibration process. This means that the reading of the values is restored to the best possible accuracy.- +

At how many points is the calibration performed / the logger verified?

The number of standard points at which the data logger is calibrated or verified depends on the model. The number and the calibration or verification points used can be found on the page of the model you are interested in.- +

The logger/sensor has an operating temperature range, but the accuracy is valid in a different range: Why?

The data loggers, whether calibration is included or on request, are calibrated at standard points in order to standardize the calibration procedures themselves. The standard points are either selected to cover as wide or as complete an operating range as possible, or they are geared to the applications in which the data loggers are mainly used. Further explanations can be found in this FAQ.- +

The logger is not measuring correctly

If the data determined by the data logger is obviously incorrect, i.e. deviates significantly from the expected data, it is likely that:- the software you are using is not the latest version. Open the tecnosoft.eu website with the software list and download the latest version of the software you are currently using.

- the logger is being used outside its shunt range. Read this FAQ.

- there is a problem with the data logger and it may be damaged. In this case, please contact our support team for instructions on how to proceed.

However, if the readings differ slightly from the expected values, the logger does not necessarily have to read incorrect values. To check the accuracy of the device, it must be tested in an environment in which the temperature, pressure and humidity parameters remain constant over a certain period of time. In addition, a reference device with a valid calibration certificate must be available to serve as a comparison for the values read by the data logger. To carry out the comparison correctly, the sensitive parts of the data logger and the reference device must be very close to each other and the ambient parameters of temperature, pressure and humidity must remain constant for a sufficient period of time, which can be between 20 and 40 minutes. If you have more than one data logger and want to compare them all with each other, it is necessary that they are programmed with the same acquisition rate for all of them and that they are placed as close as possible in this constant environment.

- +

The logger measures a different value than is shown on the display of the cell/thermometer/another logger/another device

In general, it should be noted that the accuracy of the data logger is higher than that of the displays on the refrigerators and cells and that of the usual thermometers. In addition, the reference devices used as parameters should be accompanied by a valid calibration certificate.- +

Can I recalibrate the loggers myself?

Tecnosoft has a software, Tecno Calib , which allows the user to recalibrate the data loggers independently. Tecno Calib only supports some data loggers: You can find out which data loggers are supported on the Tecno Calib page on the Tecnosoft.eu website. Suitable equipment is required to recalibrate the data loggers, such as: a calibration bath for loggers with protection class IP68 (submersible) for autoclaves or a calibration chamber for environmental loggers. Reference measuring devices such as high-precision thermometers are also required. Tecno Calib is available both with a full license, where an unlimited number of calibrations can be purchased, and with a usage-based license, where only the calibrations performed are paid for.- +

The sensor and/or circuitry of my logger has been replaced: is recalibration necessary?

Yes, because the sensor and electronics chain has been interrupted and new calibration parameters must be entered for a correct reading of the data.- +

The battery of my logger has been replaced: Is a recalibration necessary?[/toggle-titel]

No, a battery change does not lead to the loss of calibration values. Recalibration every 12 months is recommended.- +

How do I recalibrate correctly?

The calibration mode varies depending on the data logger model. If you have a waterproof and submersible data logger, such as for autoclaves or data loggers with an external tip and cable, you can immerse them in the calibration bath, otherwise the use of a calibration chamber is required. If autoclave loggers are to be calibrated, it is necessary to calibrate the entire data logger, i.e. both the sensitive part, the tip, and the electronics, as the entire data logger is exposed to the high temperatures of the sterilization process. For this reason, the entire logger must be immersed in the bath and the electronics must not be kept at room temperature by calibrating only the sensitive part or immersing the tip. It is also important that the sensitive parts are all placed close together and as close as possible to the sensitive part of the device that is used as a reference for the calibration of the data loggers.- +

How and by whom is the annual calibration carried out and what does it cost?

The annual recalibration of the devices is normally carried out in the Tecnosoft laboratories. It is sufficient to send the data loggers to Tecnosoft to request the recalibration and indicate any additional points you wish to add. The cost of calibration varies depending on the data logger model.- +

Can the data loggers be calibrated at individual points?

Tecnosoft calibration is carried out at standard points, which vary depending on the device model. It is possible to request other or additional calibration points than the standard points. The costs for these additional calibration points will be charged separately.- +

How often should the loggers be recalibrated?

The recalibration or verification of the logger depends on various factors, primarily the regulations and standards with which the company using the device must comply. It is possible that these regulations specify the maximum period for the verification or recalibration of the devices. The period also depends on the criticality of the monitored process. Finally, the measuring instruments are usually included in the quality management system procedures of an ISO 9001-certified company and the maximum period between one calibration and the next is specified. Tecnosoft recommends recalibrating the measuring devices every 12 months. Particularly intensive use of the sensors can lead to faster deviations from the correct measured value: In these cases, it is advisable to shorten this interval.- +

What type of certificate is supplied with the data loggers?

An ISO type certificate or a traceable Accredia certificate (NIST equivalent) or a second level certificate is supplied with the data loggers. Tecnosoft has its primary instruments calibrated in Accredia-certified laboratories and calibrates the data loggers with these.- +

What does ISO / Accredia traceable certificate mean?

An ISO or Accredia traceable certificate (NIST equivalent) is a second level certificate, i.e. the device to be certified has been calibrated or verified with a standard device that has been calibrated at an Accredia certified center.

Software - General

- +

Where can I download the required software?

With the system you received, you were sent a document indicating which software you need to download depending on the device and any reader base you have purchased. On the tecnosoft.eu website, click on "Software / Download" in the main menu at the top. Most of the software is managed by TecnoUtility, the first item you will find. Click on it, download it and run it. Select the software you want to install and you will find the list of supported devices. With TecnoUtility you can also update the software already installed. If the desired software is not included in Tecno Utility, go back to the website and scroll through the list of available software to find the software indicated on the document and click on it. In the "Download software" section, download the file for the item with the name and version of the software and the indication "Complete software". Once the download is complete, open the folder where you saved the zip archive and open it: extract the contents to another folder and, after opening the latter, start the installation by clicking on the "Setup" file. - +

Software is downloading, but the installation is not completed

If you encounter problems when installing the software directly from TecnoUtility, the main reason could be that one or more components of the software are having problems installing. You can work around this problem by installing the software and possibly each component manually. You can access the folder where the software was downloaded from TecnoUtility here: C:User[username]AppDataLocalTecnoSoftTecnoUtility[version] - +

The installation will not start

If you downloaded the management software for your monitoring system, you should have saved a zip archive in the folder where you downloaded the files. This is a file that contains other files in compressed form. In Windows, it is not possible to start an executable file, such as the installation of a program, from a zip archive. You must therefore open this archive and extract the files using the corresponding Extract file ... option or by dragging them into a previously created folder and starting the installation from there in the folder into which you have extracted the files. Create a folder, e.g. on the desktop or in the Downloads or Documents folders, and open it. Now double-click on the downloaded file to open it. Select all the items it contains and drag them into the folder you created earlier. Now close the folder for the downloaded file and leave the new folder open. Start the installation from there by double-clicking on the "Setup" file. - +

The software is already installed, but TecnoUtility does not recognize it

This can happen if the software has not been installed properly or has been installed in a folder other than the default folder. Select Update and then Select the installation folder. Select the folder in which your software is installed and then click Ok. - +

The software requires registration

You must fill out a registration form for Tecnosoft software the first time you start it on a new PC. The purpose of registering the software is to use it: You will receive an activation code by e-mail, which you can use to activate your license. All data collected will be stored in accordance with the European Data Protection Directive (GDPR). Registration allows Tecnosoft to provide more accurate and faster customer service. The user can also authorize the completely anonymous collection of the diagnostic data of the software and the systems themselves: this data is completely separate from the registration data. By allowing Tecnosoft to anonymously collect data on the use of the system, including the data recorded by the data loggers and the notes entered, but only the errors or anomalies, you allow Tecnosoft to improve its technical support, improve the software and even prevent possible problems. Tecnosoft thanks you for your valuable cooperation. - +

I have registered the software, but it requires a key that I do not have.

Some software requires a USB hardware protection key in order to function. To obtain this key, you must pay for the corresponding license. If you have not ordered this software, you will not have the key and will not be able to run it. As a rule, there is also a free counterpart for this software, which is available on our website. Check the scheme on page 2 of this guide to download the correct software for your devices. - +

I can't send/receive the email

If for some reason the software does not allow the email to be sent, check if your firewall is blocking the email. If the problem persists, take a screenshot of the completed form, log in to our support website support.tecnosoft.eu, open a ticket for a help request and attach the screenshot. Our technicians will send you the activation code. If you cannot find the e-mail with the registration code, check your spam folder before contacting Tecnosoft support. - +

Is there a charge for registering software?

No, you will not be charged for registering software. - +

How many PCs can I install the software on?

You can perform an unlimited number of installations on an unlimited number of PCs as long as you register your copy on each PC. - +

I have registered the software, but it requires a key that I don't have.

Some software requires a USB hardware protection key to work. To obtain this key, you must pay for the corresponding license. If you have not ordered this software, you will not have the key and will not be able to run it. As a rule, there is also a free counterpart for this software, which is available on our website. Check the scheme on page 2 of this guide to download the correct software for your devices. - +

Does the software need to be updated?

It is always good practice to use updated software. It is therefore strongly recommended to update your software as soon as a new version is available. The update may have solved some problems in your software, even if they have not occurred before, and introduces new features and improvements that will certainly be useful for your work. - +

I bought a new logger, why do I need to update the software?

If you already own a Tecnosoft system and after a certain period of time, more or less long, you buy another device that is compatible with your software, it is appropriate and in some cases even mandatory to update the software itself. The version you are currently using may predate the development of the new device you have purchased and therefore may not recognize it or process it properly. - +

Where is the user manual for the software?

Manuals or quick start guides for Tecnosoft software can be accessed via the TecnoUtility software, via any software page on our website or via the main folder of the software installed on your PC. - +

Which software enables the calculation of lethality / F0?

The software used to calculate the lethality formula (F0, A0, pasteurization units, etc.) is the following: SPD TS-Manager. - +

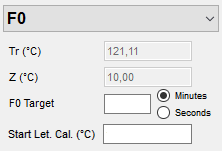

How can I set F0?

In some Tecnosoft programs, such as SPD and TS Manager, the parameters for calculating lethality (F0, PU, A0, etc.) can be entered. The user must essentially set three parameters: the reference temperature, the value of z and the cut-off. A target lethality value (to be reached or exceeded) can also be set in the TS Manager, so that after calculating the lethality value based on the recorded data, the program can immediately inform the user whether this target lethality value has been reached or not. These parameters are set differently depending on the software, so it is advisable to follow the specific instructions of each software. Tecnosoft does not specify the parameters to be entered, as these must be set by the operator carrying out the process or validation. - +

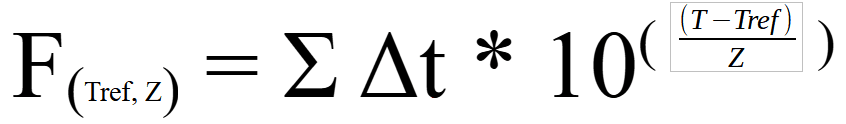

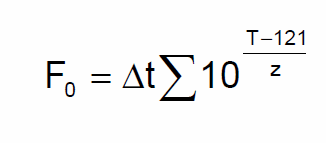

Which formula is used for F0?

The software that implements the lethality formula, TS Manager and SPD, use the international standard formula and both allow you to set the reference temperature (Tref), the Z value and the minimum temperature value to be considered for the contributions to the calculation. end of lethality.The formula implemented is the following:

t = time

T = temperature

For all our measurements, Δt is of course a constant. The formula can therefore also be expressed by using the standard value for the reference temperature for the calculation of F0:

- +

The device does not establish a connection / the software does not recognize my logger

The reasons why the connection between the data logger and the software is not established can be manifold. If you have several devices and none of them are connected, the problem could be due to the interface or the software configuration. If you have several devices and only one does not establish a connection, please refer to the instructions for your device. Check that the interface is correctly connected to the PC and that the logger is inserted correctly. Make sure that the parts that touch each other are dry and clean. Try disconnecting and reconnecting the interface after waiting a few seconds. You can also check that the USB drivers are installed correctly: To do this, open the Device Manager in the Windows Control Panel (access to this depends on both your version of Windows and the display mode you have set; in Windows 7 and 10, you can click Start and type "Device Manager" to find it). Check whether your interface is listed under "Ports (COM and LPT)" or under "USB Controller" (depending on the interface) without a note or warning symbol. If there are signs of problems, right-click on the interface and click on Update driver. Select the option to search for drivers on your computer and open the folder where the drivers are located (in the Driver folder in the file downloaded with the software or in the installation folder of the software itself). You can also consult the following FAQs:- SPD Software - Does not connect

- TS Manager Software - The logger does not connect

- High Temperature Data Logger - The logger does not connect

- +

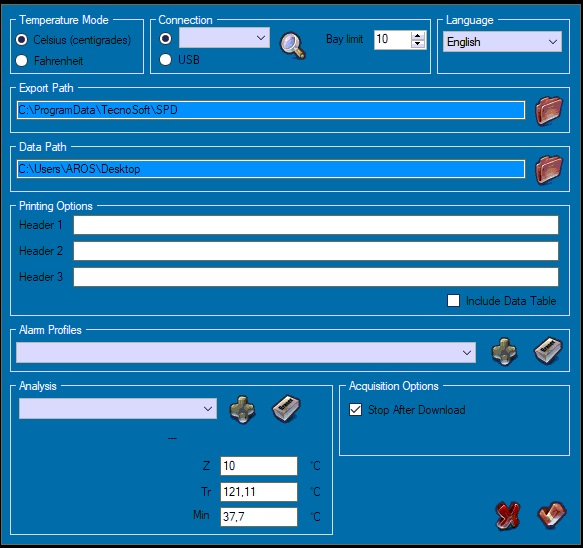

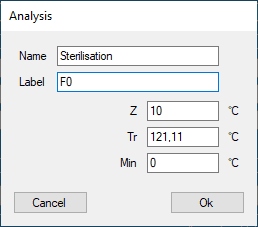

How can I calculate FO?

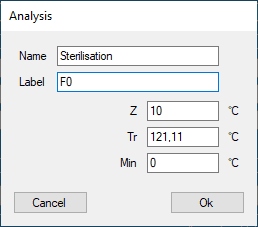

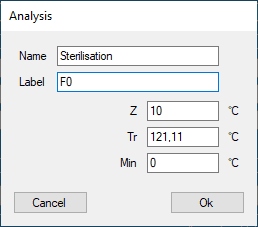

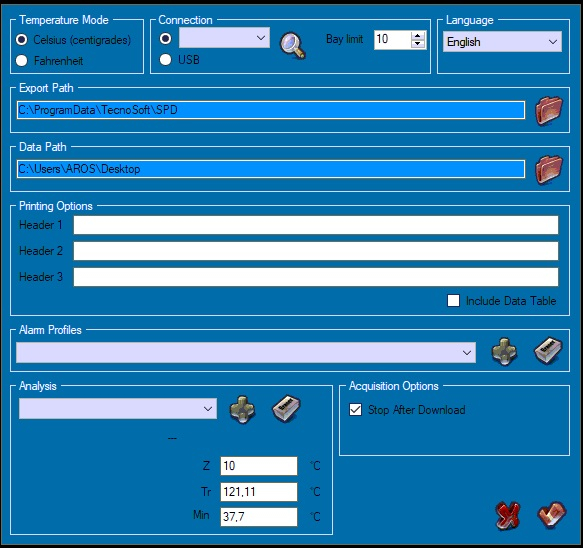

Start the software, click on the gear icon at the bottom right and create a profile for the lethality calculation.

Click on the "+" symbol in the analysis field.

Assign a name and a designation to the analysis, e.g. F0.

Specify the values for Z, Tr (reference temperature) and Min, the minimum temperature value from which the lethality calculation begins). Click OK to confirm. At this point, you can select the desired profile from the drop-down menu to analyze the data in the archive.

Analysis profiles only affect downloaded data, not the start of the logger.

- +

Why is the F0 label not printed when the report is generated?

The F0 label or another label that you want to assign to the lethality calculation when printing the report, but also in the diagram window of the SPD software, must be defined when creating the analysis profile. If no label is specified, the field is printed without a label. - +

What do the parameters for calculating mortality mean?

Note: You can find out how to define the parameters for calculating the lethality in the FAQ How do I calculate F0? (see above) Lethality is a time whose value is used to evaluate a thermal process such as sterilization or pasteurization. The variables that must be inserted in the formula areTr (reference temperature): the theoretical temperature at which the process should remain constant. Usually the following is given: "I sterilize at 121°C for 10 minutes". 121°C is the reference temperature.

Z: this is also a temperature that indicates the increase in temperature that must be applied to the reference temperature to reduce the time to a tenth. This parameter is linked to a specific microorganism. For example, if it takes 10 minutes at 121°C to achieve a specific reduction of a specific microorganism and the Z value is 10°C for that specific microorganism, it will take 1 minute at 131°C to achieve the same reduction.

Min: the minimum temperature at which the lethality calculation should start. Any contributions to the final result recorded at a lower temperature than the one set in the "Min" field will not be taken into account.

Depending on the parameters used in the formula and the purpose of the thermal process, there may be different designations:

F0: standard sterilization when the reference temperature is 121.11°C (250°F) and the Z value is 10 (botulinum)

FT: where T stands for a reference temperature other than 121°C. It could be F134, F110, etc. The Z value can also be different from 10

PU: pasteurization units denoting a process with a reference temperature usually below 100°C.

A080: used for washer-disinfectors with a reference temperature of 80°C

A090: used for washer-disinfectors with a reference temperature of 90°C

A0T: forwasher-disinfectors with a reference temperature that can be set by the user.

See also our tutorial on the lethality formula. Insert VIDEO!

- +

I did not set the correct F0/lethality profile before starting the logger: Do I need to repeat the test?

The lethality analysis profiles (see this FAQ) for the calculation of lethality based on the parameters set in the software and the data recorded by the data loggers only affect the downloaded data, both when downloading from the currently connected logger and when opening the data in the archive.

Therefore, it is not necessary to set the correct profile for the process you want to perform before starting the loggers, but only when you want to analyze the data. If you have data in the archive and select different analysis profiles in the configuration and reopen these missions, you will find different lethality values. - +

What does it mean that a synchronization error has occurred?

If a synchronization error occurs when connecting the logger to the SPD, this means that the device's clock is not synchronized with that of the PC to which it is connected, i.e. there is a difference of more than 5 minutes.There are many reasons for this:

- the logger's battery has been replaced, causing the date and time to be lost

- the logger has reset itself, perhaps due to a low battery and / or because it has been exposed to high or low temperatures

- the PC has an incorrect date/time

- the logger was programmed with one PC and downloaded with another and the two PCs are not synchronized

- the PC is set to a different time zone than the logger at startup

When you start the logger, it will synchronize with the PC.

Calibration / measurement error

- +

What is meant by the validity of the accuracy in the calibration range?

The data loggers have an operating range, i.e. a range in which the logger can operate in its entirety, a sensor operating range, i.e. the range in which only the sensor covering the logger (i.e. without electronics and batteries) can operate, and a calibration range, i.e. a range in which the logger is actually calibrated. Regardless of whether the loggers are supplied with a calibration certificate or on request, standard calibrations are performed at fixed points that are the same for all in order to standardize the calibration processes. However, it is possible to request additional points within this standard calibration range and even beyond for some objects: In this case, the calibration range of the logger is extended. The specified accuracy only refers to the calibration range, as the points of the calibration curve are corrected exactly within this range. Only some loggers have good accuracy even outside the calibration range, which reduces the accuracy away from the extreme values of the calibration range itself. These loggers are: -S-MicroW - S-Disk J - PressureDiskFor other models, the accuracy outside the calibration range is unpredictable. For this reason, it is advisable to check the calibration code when selecting the monitoring system and request additional points if necessary.

Example:

Let's take the S-Micro L for example.

These are its characteristics:

Operating range: -40 ° C ÷ + 140 ° C

Sensor operating range: -40 ° C ÷ + 220 ° C

Calibration range: 25° C ÷ + 140° CThis means that the logger can withstand temperatures from -40 ° C to 140 ° C. The sensor can withstand and read temperatures from -40 ° C to 220 ° C, but is calibrated in the range from 25 ° C to 140 ° C. The stated accuracy of +/- 0.1°C applies in the latter range, and if I wanted to use it for monitoring at lower temperatures, for example, I would need additional points (for example 0°C). Apart from the loggers mentioned above (S-MicroW, S-Disk and PressureDisk), all others require an additional point at least every 25/30 °C to achieve good accuracy.

Note: It is possible that the accuracy may be lower than specified due to the extension of the calibration range.

- +

The logger is not measuring correctly

If the data recorded by the data logger is obviously incorrect, i.e. deviates significantly from the expected data, it is likely that:

- The software you are using is not the latest version. Go to the tecnosoft.eu website with the software list and download the latest version of the software you are currently using.

- The logger is being used outside its shunt range. Read this FAQ.

- There is a problem with the data logger and it may be damaged. In this case, contact Tecnosoft support for instructions on how to proceed.

However, if the readings differ slightly from the expected values, it is not necessary that the logger is actually reading incorrect values. To check the accuracy of the device, it must be tested in an environment in which the temperature, pressure and humidity parameters remain constant over a certain period of time. In addition, a reference device with a valid calibration certificate must be available to serve as a comparison for the values read by the data logger. To carry out the comparison correctly, the sensitive parts of the data logger and the reference device must be very close to each other and the ambient parameters of temperature, pressure and humidity must not fluctuate over a sufficient period of time, which can be between 20 and 40 minutes. If you have more than one data logger and want to compare them all with each other, it is necessary that they are programmed with the same acquisition rate for all of them and that they are in as constant an environment as possible. If you still have doubts about the accuracy of the measured values, please contact Tecnosoft support.

- +

The logger measures a different value than is shown on the display of the cell/thermometer/another logger/another device

To make a real comparison, read this FAQ. In general, it should be noted that the accuracy of the data logger is higher than that of the displays on the refrigerators and cells and the usual thermometers. In addition, the reference devices used as parameters should be accompanied by a valid calibration certificate - +

The loggers do not determine the same values

If it is determined in a repeatable manner that the loggers used in the same environment do not match, a comparison check can be carried out. It should generally be noted that an environment with constant parameters over time must be used for these comparisons. For this reason, tests carried out in cells, rooms, refrigerators, autoclaves, pasteurizers or other types of machines are not considered valid, as the temperature in these rooms is either not constant over a sufficient period of time or is not uniform. However, it is possible to make a comparison between the loggers depending on the equipment you are using. If the data loggers are set for ambient temperatures from -30°C to 60°C, you can program them all with the same logging time and place them, for example, in a refrigerator or locked in a separate room, cupboard, box and let them record for a day and a night. A very simple test can be carried out on loggers with IP68 protection, i.e. which are submersible and can withstand high temperatures above 100 °C: Program the loggers with a logging time of 30 seconds and boil water in a pot. As soon as the water boils, place the loggers in the water with the sensitive part facing upwards. Wait 20 minutes, then you can remove the water from the stove and wait for it to cool down. Once it has cooled down, you can remove the loggers and download the data for comparison. The loggers should all have reached the same temperature of about 100 degrees after about 15 minutes

Battery

- +

Are the batteries in the data loggers rechargeable?

The batteries in the data loggers are not rechargeable, and we do not recommend using commercially available rechargeable batteries in the loggers that allow this, as this could affect the quality of operation of the device itself. - +

How should the S-Micro (or P-Micro) battery be inserted?

The positive side of the S-Micro / P-Micro battery is the side on which the serigraphy is located and must be positioned in the direction of the data logger's circuit. The other side without engraving, the negative side, is positioned with the spring pointing downwards.

- +

How long does the battery last?

The battery life specified on the data sheet is calculated on the basis of the logger's normal consumption and should be taken as a rough guide. Battery consumption naturally depends on the use of the device and above all on the set logging rate and the operating temperature: the higher or lower this is, the higher the consumption.

In addition, lithium batteries do not have a discharge curve like alkaline batteries, but more or less hold their nominal voltage almost to exhaustion and then suddenly collapse.

Another caveat is that if you connect the loggers when they are still very hot or very cold, you might get low battery voltage readings, but once they return to room temperature, the readings will also return to normal.

- +

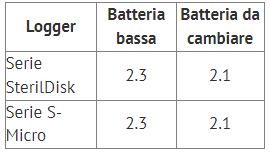

When should the battery be replaced?

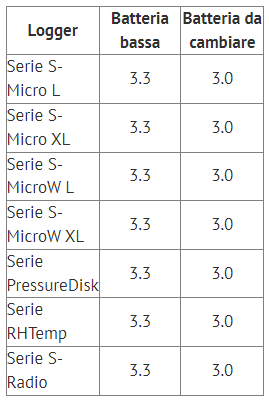

Most of our data loggers have user-replaceable batteries. The software usually indicates when the battery needs to be replaced.Logger with 3.0 V battery

Logger with 3.6 V battery

- +

How can I change the battery in my logger?

USB driver

- +

How can I install the necessary drivers and ensure that they have been installed correctly?

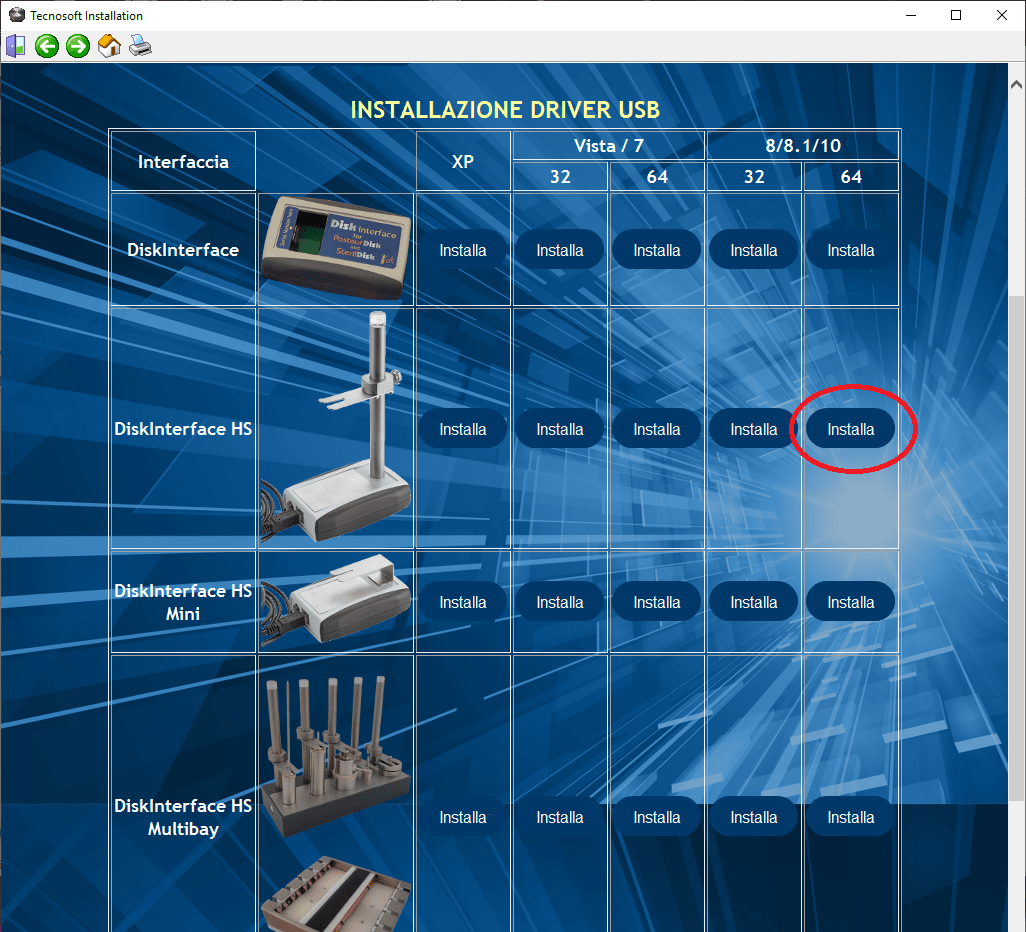

When installing some software, the USB drivers for the available interface(s) are installed automatically. For other software, however, the drivers must be installed manually. This is possible via the software installation menu, which contains a table with the image of the available interfaces (search for yours) and the list of operating systems for which drivers are available. Click on the Install button located in the cell where your interface and operating system intersect. For example, if you have the DiskInterface HS and Windows 10 64-bit, click on the specified button:

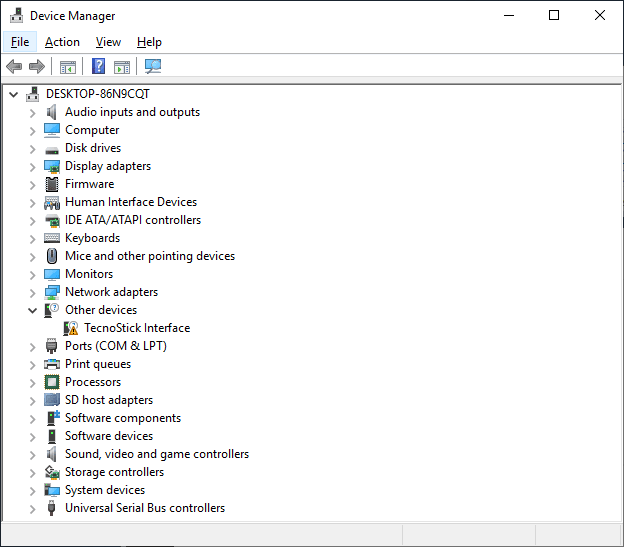

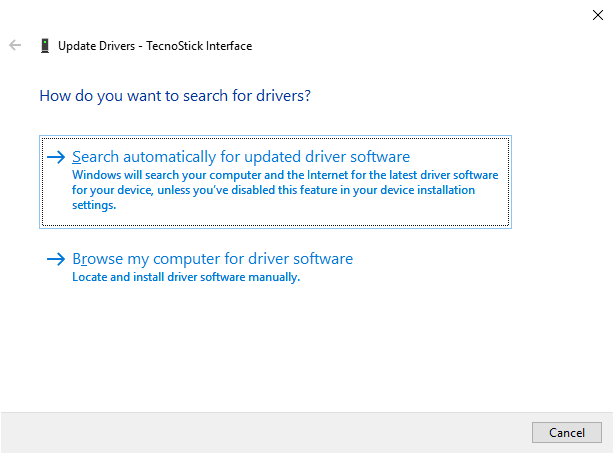

You may need to install the drivers manually via the Control Panel. Open the Device Manager (it can be accessed in different ways depending on the operating system. Read the relevant FAQ) and search for your device. If you have opted for manual installation, there is probably a connection problem, which is why the device is displayed at the top of the list as unknown or with a warning symbol, indicating that it has not been installed correctly.

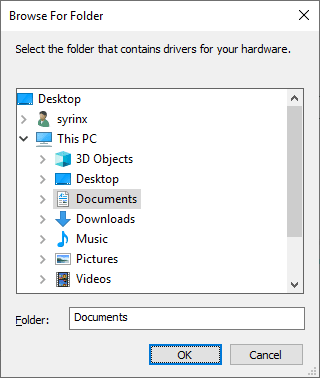

Right-click and select Update drivers. Select the second option, Search for driver software on the computer, and click Browse to select the folder where the drivers are located.

They are located in the zip archive that you downloaded from the tecnosoft.eu website and that you have already extracted to a PC folder, in the Driver folder, which is divided by operating system. Select the folder for your operating system, click OK and then Next. The drivers will now be installed. Note: Windows drivers and authorizations for application installation are required for the installation of drivers, e.g. for the installation of software.

SPD software

- +

The logger will not connect

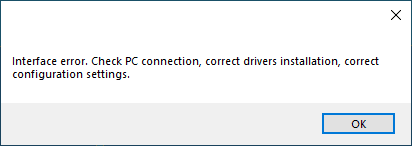

The reasons why the logger will not connect to the software can be different. First, you need to see what the error message provided by the program is. If the error message refers to the reader base or interface, as in the figure below, this means that the problems encountered are most likely to be found only on the interface.

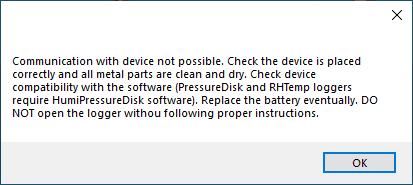

Therefore, check that the cable is correctly connected to the PC and the interface and that the drivers are correctly installed. To install the drivers, please read the instructions for the interface you are using and the operating system under which you have installed the software. If, on the other hand, an error message refers to the data logger, as in the illustration below, follow the instructions on the screen to check its function.

First, dry clean all metal parts of both the data logger and the interface. Secondly, check that you have positioned the data logger correctly: the tip or sensitive part must always face upwards and the side with the writings, with the laser marking, must always face downwards. Of course, this does not apply to cylindrical loggers, which must be positioned upright with the tip pointing upwards.

Check whether the metal parts of the interface adhere to the metal parts of the data logger. Also try disconnecting the interface and connecting it to both the same and another USB port, and make sure that the USB drivers are also installed on this second port. One of the main reasons why the logger does not connect is a low battery. To check this, follow the instructions in the video tutorial on the Tecnosoft YouTube channel to learn how to properly open the logger and remove the battery.

You can test the battery with a tester. If you have a spare battery, replace it. In addition to the battery, remember to replace the O-rings to ensure the logger is sealed under water and under pressure.

If the battery is charged or no connection can be established even after replacing the logger, you can carry out a simple test with a tester.If the problem persists, contact technical customer service to find out how to proceed.

WARNING! The PressureDisk, Pirani and RHTemp series loggers are NOT supported by the SPD software. You must use the HumiPressureDisk or TS Manager software (if you have the USB stick).

- +

Where are the measured values saved?

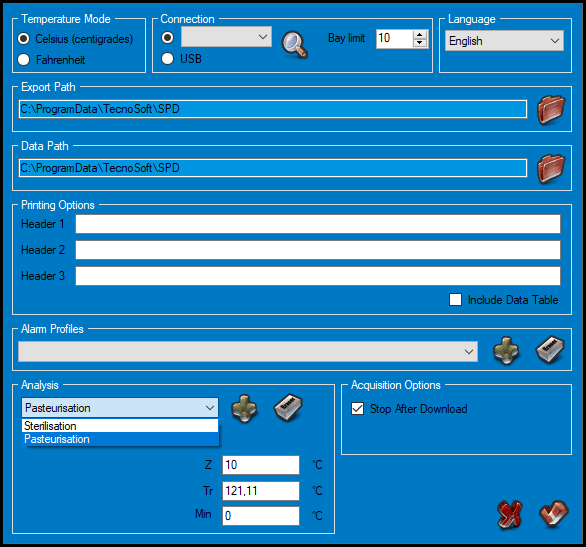

To find out the folder where the missions downloaded from the data logger are saved by the SPD, open the program and click on the cogwheel at the bottom right to open the configuration window.

The Data Path field displays the folder where the downloaded mission files are saved; you can change this folder by clicking the Browse button to the right of the field. If you change this folder, click Confirm. When you open the archive, you will not find any missions. However, the data has remained in the old folder, so you will need to open the old folder and move the files to the new folder. Another way to find out where the data is located, besides the name of the file belonging to a mission, is to open the archive and highlight the mission you are interested in without double-clicking on it. You will find the path and name of the file in the bar at the bottom of the archive window.

- +

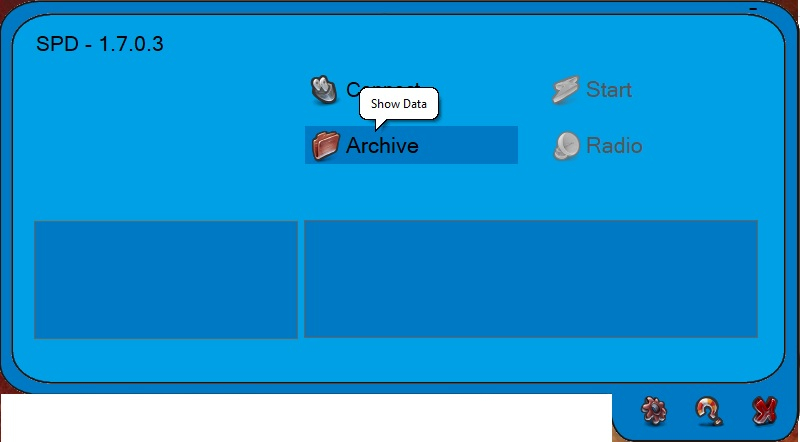

How can I view historical records?

To view previously saved operations, open the program and click on Archive. A window opens that is divided into two lists: on the left side you will find the missions that were downloaded directly from the memory of the loggers, on the right side the missions that were received via radio from the s-radio data loggers. To open a mission, double-click on it or select it and click on the button with the checkmark to confirm.

Another way to open a mission is, after opening the SPD program, to drag the .dat file onto the main program window and release the mouse button: the selected mission will be opened immediately.

Pressure Monitoring

- +

Does PressureDisk measure the relative pressure?

No, the pressure measured by the PressureDisk is absolute. When monitoring the pressure in a closed and watertight environment (the autoclave), it is not normally possible to determine the atmospheric pressure as there is no access to the external environment (see this FAQ). The TS Manager software also allows you to view the downloaded data with relative pressure values. - +

What do relative pressure and absolute pressure mean?

Pressure can be measured in absolute or relative terms, depending on whether the atmospheric pressure of 1 bar at sea level is taken into account. We are all exposed to a pressure of 1 bar given by the column of air in the atmosphere above and around us. As this is the normal state we are all in, the point 0 can be considered as the measuring point for pressure, and in this case we speak of relative pressure, as it does not take atmospheric pressure into account. Absolute pressure, on the other hand, takes it into account and therefore the initial condition is no longer 0, but 1 bar.If we were to seal an airtight container at sea level, we would have a relative pressure of 0 bar and an absolute pressure of 1 bar. If we could extract air from inside the container, we would have a negative relative pressure and an absolute pressure of less than 1. It is not possible to achieve a perfect relative pressure or absolute pressure of 0, as it is impossible to achieve a perfect vacuum. If we open and close the same container again and then return to the initial conditions (0 bar relative, 1 bar absolute), we could increase the internal pressure by 1 bar, we would have 1 bar relative pressure (0 + 1) and 2 bar absolute pressure (1 + 1) and so on.

For a sensor to measure relative pressure, it must be able to measure the pressure in a given environment and compare it to atmospheric pressure, which cannot always be 0 bar for relative pressure and 1 bar for absolute pressure, as it varies depending on weather conditions.

- +

The pressure data recorded by PressureDisk differs from that of my autoclave!

Most likely, the autoclave displays the data in relative pressure, while the PressureDisk records the absolute pressure. If the values on the display of the autoclave are about 1 bar lower than those of the PressureDisk, then this is certainly the explanation. See this FAQ for further explanation.- +

Why does a hot data logger show a different pressure than one at room temperature? INSERT IMAGE

The pressure is related to the temperature and we correct the two parameters during calibration. Given the metal mass of the data loggers and their slow cooling after leaving the autoclave, the ambient pressure recorded by this device during cooling, i.e. at a variable temperature, may differ slightly from the ambient pressure of a device that is at a stable temperature. When the logger stabilizes its temperature, the pressure recorded by the two loggers must equalize.

PressureDisk Data Logger

- +

PressureDisk will not connect

If your PressureDisk series logger will not connect, first make sure you are using the latest version of compatible software such as TS Manager or HumiPressureDisk (ATTENTION: SPD IS NOT COMPATIBLE WITH PRESSUREDISK). - +

Can I bring the PressureDisk into direct contact with the product (sauce, oil, canned food, etc.)?

The PressureDisk is made of food-safe materials. It can be inserted directly into a container that is in contact with the product, be it solid, semi-solid or liquid. However, it is very important that the logger is cleaned very well at the end of the process, especially in the photo above, with water only. Do NOT insert ANYTHING into the hole to clean it, just run some water. If the product remains in the hole where the pressure sensor is located, there is a risk that the sensor will be blocked by further settling and the pressure can no longer be recorded correctly. For the same reason, do not insert anything into the hole for cleaning, as there is a risk of the sensor itself burning up.- +

What are the standard calibration points of the PressureDisk?

The standard temperature calibration points of the PressureDisk (not PressureDisk 05) are those of all loggers for high temperatures: 25/50/75/100/121/140 ° C. The standard pressure calibration points are: 50 / 1k / 2k / 3k / 4k mbar absolute. In reality, each of these pressure points is calibrated at 5 different temperatures, covering the entire operating range of the loggers, from room temperature up to 140 °C. Therefore, the actual pressure calibration of the PressureDisk consists of 25 different points. However, only the 5 pressure points with a single reference temperature to which the pressure has been calibrated are indicated on the calibration certificate, while the other 4 temperature points are omitted. This decision is due to the desire to indicate the most important temperature for this pressure point, as there is a clear correlation between temperature and pressure in the main use environment of the device, a steam autoclave.

Radio Systems

- +

Radio, wireless or WiFi?

Wireless: Device or communication system that does not use wires/cables. Literally, it does not mean that there is radio transmission or a radio antenna, even though it is used today to define radio transmission. Technically, for example, the SterilDisk is "wireless" because it works without wires and powers itself, even though today when we say "wireless" we mean radio transmission, which is why we will not use this term for non-radio systems.

Radio: any type of transmission that uses radio waves of any type and therefore any protocol (the protocol is a specific method of radio communication).

WiFi: is a type of radio communication, but does not mean "wireless" and does not indicate a type of radio transmission. It is characterized by a precise protocol and defined transmission frequencies.

High temperature data logger

- +

Logger won't connect

There are many reasons why a logger won't connect. Maybe the battery is dead and you need to replace it. On our Youtube channel you will find instructions on how to replace the battery for each logger type. Maybe you have already replaced the battery, but with the wrong polarity. Another reason is that the logger has not been closed properly or has not been dried and cleaned properly. The PC connection is a combination of many different small connections: The battery must be inserted correctly and the spring must remain straight and touch the center of the circuit. If you bend the spring when closing it, it will no longer touch the golden connecting strips on the circuit after the battery has been replaced. The logger must then be closed well so that the spring is pressed down and the battery can make a good connection with the ground. The metal parts must be clean and dry, also at the interface. The movable fork of the DiskInterface HS or the Multibay must be pressed onto the logger and not just rest on it. Try to press it down with your finger and see if it clicks into place. It could be slightly bent and not make a good connection. If you replace the battery, all loggers will be faulty. Just start them up to synchronize them with the PC. - +

What are the costs for spare parts and recurring costs?

The only part that needs to be replaced regularly in the data loggers is the battery, and the cost varies depending on the data logger model. The battery kit that includes a new battery also includes the hole or ring if more than one is required. Each time the data logger is opened, the sealing ring must be replaced to ensure pressure tightness and prevent steam or liquids from entering the data logger. The sealing ring can also be purchased separately. - +

The sensor/circuit (or both) has been replaced on my logger. Why do I have to recalibrate the logger?

If the sensor and the circuit, or even just one of them, are replaced, the calibration chain is interrupted. This is because the calibration does not only depend on the sensitive element, but is a mixture of variations depending on the temperature to which the electronics and sensor unit is exposed. In fact, both vary with temperature and therefore both need to be calibrated. Since the autoclave devices are fully exposed to the high temperatures of the sterilization process, i.e. both the electronics and the sensor, Tecnosoft fully immerses the logger in a calibration bath to calibrate the entire logger. If one of these two parts is replaced, the unique chain is broken and it is therefore necessary to recalibrate the entire system. - +

Are the S-MicroW and PressureDisk models suitable for the thermal validation of autoclaves?

The TS Manager solution consists of the software of the same name, which is compatible with the FDA 21 CFR Part 11 and the GAMP5 standard, together with the S-MicroW and PressureDisk series data loggers and the DiskInterface HS and Multibay read bases and was developed specifically for the validation of thermal processes in autoclaves, but not only. It can also be used for the validation of instrument washers, pasteurizers, other food production machines, warehouses and refrigerators, both in the medical and pharmaceutical food industries. - +

What are the running costs for batteries and how long does delivery take?)

Usually the batteries are in stock. Therefore, they can be shipped in a short time. The costs depend on the data logger model - +

Can the loggers be repaired in the event of damage? Who will carry out the repair and where will it be carried out? How long is the lead time?

Depending on the type of damage, the data logger can be repaired or replaced. In the case of mechanical breakage, such as breakage of the housing or the tip, the part can be replaced. However, the logger cannot be repaired if these breakages have allowed steam or water to enter the data logger itself, damaging the circuit (the electronics), the sensor (the sensitive part) and the battery. In this case, all parts need to be replaced, so it is better to buy a new data logger. There are two other parts that can be replaced, namely the electronics and the sensor. Upon receipt of the logger, it will be analyzed by Tecnosoft to determine the damaged part and provide an estimate for the replacement. The warranty granted by Tecnosoft lasts 12 months and covers the replacement of the circuit and the sensor. Mechanical damage and batteries are not covered. If the sensor and / or the circuit need to be replaced, the data logger must be recalibrated as the calibration chain has been interrupted.

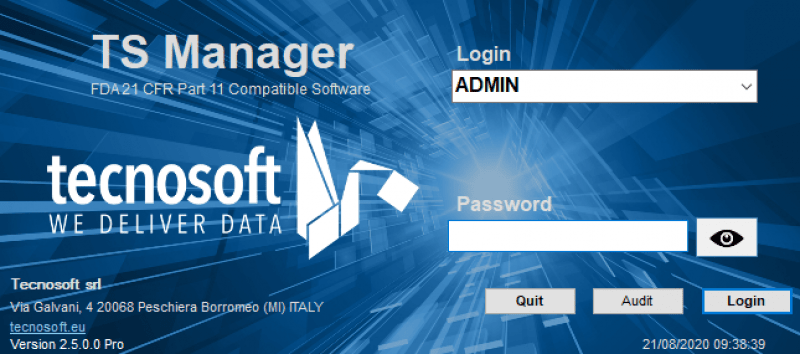

TS Manager Software

- +

The logger does not establish a connection

If the data logger plugged into the interface does not establish a connection, follow the instructions in this FAQ.

For the high-temperature loggers managed by the TS Manager, you can follow these further instructions.

Firstly, all metal parts of both the data logger and the interface must be cleaned dry. Secondly, check that you have positioned the data logger correctly: the tip or sensitive part must always face upwards and the side with the writings, with the laser marking, must always face downwards. Of course, this does not apply to cylindrical loggers, which must be positioned upright with the tip pointing upwards.Check that the metal parts of the interface adhere to the metal parts of the data logger. Also try disconnecting the interface and connecting it to both the same USB port and another USB port and make sure that the USB drivers are also installed on this second port. One of the main reasons why the logger does not connect is a low battery. To check this, follow the instructions in the video tutorial on the YouTube channel to learn how to properly open the logger and remove the battery.

You can test the battery with a tester. If you have a spare battery, replace it. In addition to the battery, remember to replace the O-rings to ensure the logger is sealed under water and under pressure.

If the battery is charged or no connection can be established even after replacing the logger, you can carry out a simple test with a tester.If the problem persists, contact technical support to find out how to proceed.

- +

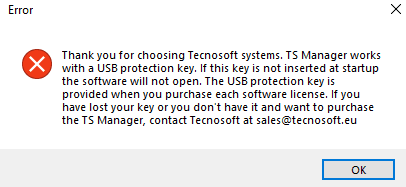

USB protection key error message

If an error message appears when you start the TS Manager prompting you to insert a USB protection key, you need to check that the key you received when you purchased your validation system is actually plugged into a USB port on your PC.

If you did not purchase the TS Manager software, you do not have this key. You can still use other software depending on which loggers you purchased: SPD or HumiPressureDisk.

If the key is inserted and the message still appears, this means that it is damaged: In this case, contact Tecnosoft customer service.

- +

I am locked, but I need to log in urgently

If you are locked, you will not be able to log in until the lock is lifted. Contact customer service to request that the block be lifted and explain the urgency of the situation. They will be able to help you.

- +

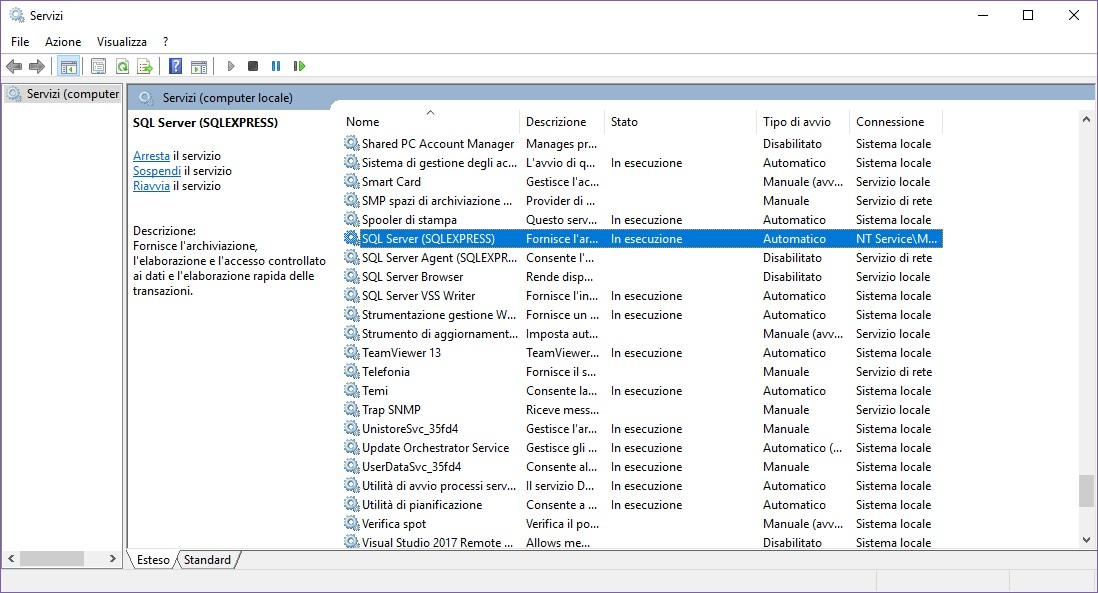

An error is displayed when connecting to the database

To check whether Microsoft MS SQL Server is properly installed and activated, open the Services window in the Control Panel (in Windows 10 you can simply open it by clicking on Start and entering Services).

Search for the instance name and check if it is running. Search for SQL Server (instance name) and check whether the entry Running is in the Status column. If not, right-click on it and select Execute.

- +

Can I delete a mission?

This depends on the software you are using and the permissions you have. Some software allows you to delete missions, others do not. Refer to the software's documentation or contact customer service for more information. They will be able to help you with how to delete a mission. - +

Can I create a group with a single mission?

This depends on the software you are using. Some programs allow you to create a group with a single mission, while others require multiple missions to create a group. Check the documentation for the software or contact customer support for more information. They will be able to help you further on how to create a group with a single order. - +

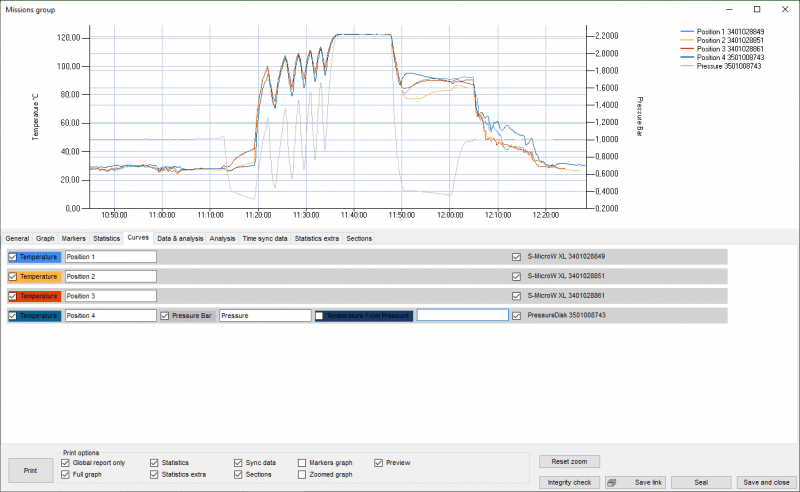

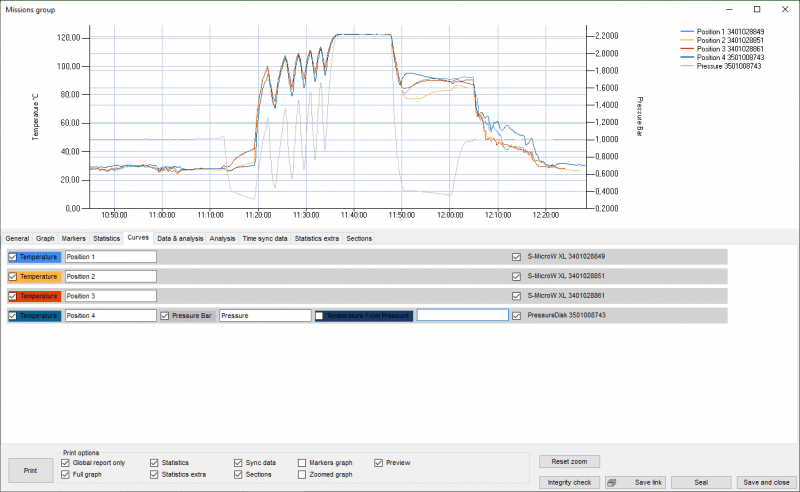

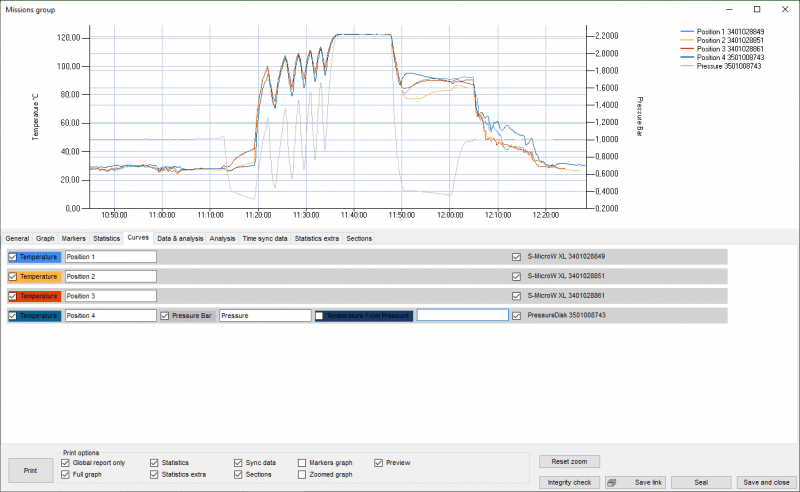

Can I add missions from different device models to a group? How many missions can I group together?

Yes, you can. There is no limit to the number of missions you can add to a group.

- +

Can I create a group with temperature, pressure and humidity?

No, this is not possible: a group can only contain two physical variables.

- +

Can I create a group with two pressure curves?

Yes, you can.

- +

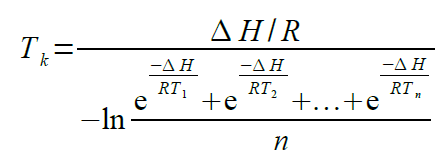

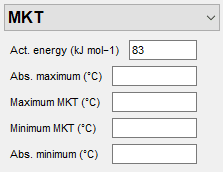

What is MKT?

Mean kinetic temperature (MKT) is defined by the ICH as: "A single derived temperature which, when maintained over a period of time, represents the same thermal stress to a drug substance or drug product as would occur over a range of both higher and lower temperatures over an equivalent period of time. The mean kinetic temperature is higher than the arithmetic mean temperature and takes into account the Arrhenius equation.

Therefore, the mean kinetic temperature can be considered as an isothermal storage temperature that simulates the non-isothermal effects of storage temperature fluctuations. It is not a simple arithmetic mean, but an exponential and logarithmic relationship.

The Haynes formula can be used to calculate the MKT. It is higher than the arithmetic mean and takes into account the Arrhenius equation from which Haynes derived his formula. Thus, MKT is the only calculated temperature that stimulates the non-isothermal effects of bearing temperature fluctuations.

- Tk = MKT in ºK

- ΔH = heat of activation / activation energy

- R = Universal gas constant (8.3144? # 10-3 kJ.Mole-1 # ºK-1)

- Ti = Temperature in ºK

- n = total number of equal time periods over which data is collected

The mean kinetic temperature refers to a reference point that can be calculated from a series of temperatures.

It differs from other means in that higher temperatures are weighted more heavily when calculating the average.

This weighting is determined by a geometric transformation, the natural logarithm of the temperature number.

The disproportionate weighting of higher temperatures in a temperature series according to the MKT takes into account the fact that the thermal decomposition of materials accelerates at these higher temperatures. The MKT takes this non-linear effect of temperature into account.

It is calculated from the average storage temperatures recorded over a certain period of time and a running average, which is the average of the weekly maximum and minimum temperatures. For MKT to be meaningful, an appropriate number of temperature/time sample points should be used. MKT may only be used in situations where the temperature of the storage area is well controlled but there are occasional deviations due to seasonal variations.

MKT may only be used in cases where the scientific data on the thermal stability of the product concerned, used to establish the original storage conditions stated on the label, allow limited deviations between 25ºC and 30ºC. The marketing authorization holder should be asked whether these deviations affect the thermal stability of the products in question and therefore whether or not the use of MCT is applicable.

Strict conditions should apply to the use of MKT, i.e:- It is only suitable for storage of products under controlled room temperature (e.g. products labeled "Do not store above 25 ºC").

- MKT is not suitable for products that require controlled storage at low temperatures.

- MKT cannot be used to compensate for poor temperature control of storage facilities, e.g. due to poor construction.

- Any exceedance of the storage requirements for products stated on the label should be documented, investigated and reported to the marketing authorization holder.

- Actual storage temperatures should not exceed 30ºC at any time if MKT is to be applied, i.e. with a MKT of 25ºC, variations between 15ºC and 30ºC are acceptable.

- +

What is lethality?

Lethality is a time whose value is used to evaluate a thermal process such as sterilization or pasteurization. The variables that must be inserted into the formula are:

- Tr (°C) (reference temperature): the theoretical temperature at which the process should remain constant. Usually the following is stated: "I sterilize at 121°C for 10 minutes". 121°C is the reference temperature.

- Z (°C): This is also a temperature that indicates the increase in temperature that must be applied to the reference temperature to reduce the time to a tenth. This parameter is linked to a specific microorganism. For example, if it takes 10 minutes at 121°C to achieve a certain reduction of a specific microorganism and the Z value is 10°C for that specific microorganism, it will take 1 minute at 131°C to achieve the same reduction.

- F0 target: the target lethality result you want to achieve with your process, expressed in minutes and seconds

- Start Let. Cal (°C) (start lethality calculation): the minimum temperature from which the lethality calculation should be started. All contributions to the final result that were recorded at lower temperatures than those set in the field are not taken into account.

Depending on the parameters used in the formula and the purpose of the thermal process, it may have different designations:

- F0: standard sterilization when the reference temperature is 121.11°C (250°F) and the Z value is 10 (botulinum)

- FT: where T stands for a reference temperature other than 121°C. This can be F134, F110 etc. The Z value can also deviate from 10

- PU: pasteurization units indicating a process with a reference temperature normally below 100°C.

- A080: used for washer-disinfectors with a reference temperature of 80°C

- A090: used for washer-disinfectors with a reference temperature of 90°C A0T: used for washer-disinfectors with a user-adjustable reference temperature

- +

What is the vacuum leak test?

The vacuum leak test is a test for autoclaves required by the UNI EN ISO 13060 standard. It consists of checking whether there is a fixed increase in pressure between two specific periods of the process. This is to ensure that there are no leaks in the system.

- +

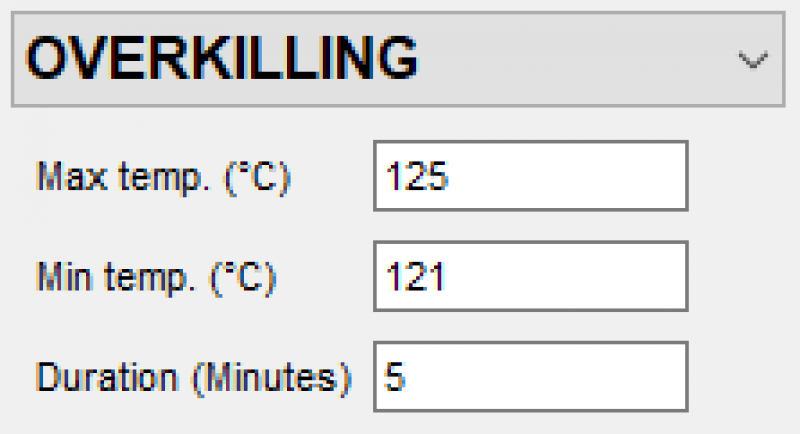

What is overkilling?

Overkilling is a method for checking autoclaves. It consists of setting two limit values and a duration and checking whether the temperature remains within these two limit values for the specified period of time. These values are sometimes specified by the manufacturer.

- +

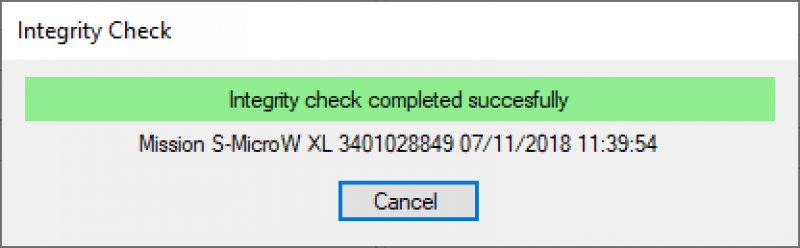

What does it mean that the data is encrypted?

This means that if you open this file with an editor or other software, you will not be able to understand the content as it has been written in a special encoding format. The content can be edited, but the result is a hacked and corrupted file that can no longer be opened.

- +

I need to make a backup copy, but I don't have administrator rights

It is still possible to make a backup copy of the database, but not to restore it, even if you don't have administrator rights. You can create a guest user in the login window and guest users can create a backup. - +

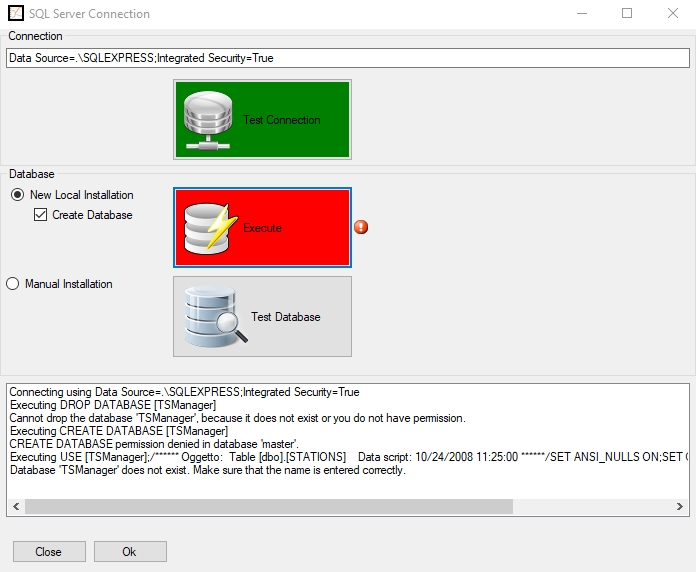

When I try to create a new data query, a permission error occurs

During the creation of the database, the process is interrupted due to a denied permission. The error reported is: The database "TS Manager" cannot be deleted because it does not exist or you do not have authorization.

In this case, the Windows user who is currently logged in does not have the necessary rights to create the database. To avoid this problem, it is necessary to add ;User Instance=True to the connection string in the Connection field.

The result in the case shown in the figure would be as follows: Data Source=.SQLEXPRESS;Integrated Security=True;User Instance=True where SQLEXPRESS is the SQL instance currently in use (SQLEXPRESS is the default instance, check if your instance is different. You can refer to this FAQ). Then click Test connection again, wait for the test to complete and then click Run. The button will turn green if the test was successful. Please note that the database was created for the current Windows user and you cannot access it from another Windows account. If you want all users to be able to access the same database, you must ask your IT manager to grant access and write permissions to the database using the specific Microsoft tools.

General troubleshooting

- +

Nothing works and I don't know what to do!

What to do if a problem occurs:- First check the website to see if there is a newer version of the software. It is possible that a problem has already been solved in an earlier version. No tickets are opened for old versions of the software.

- Secondly, check the FAQ to see if there is already a solution to the problem you are reporting.

- If there is no FAQ for your report, send a report to Tecnosoft with the following information:

-

- Serial number of the data logger:

- Name of the software used:

- Version of the software used:

- Detailed description of the problem, possibly with screenshots (if the problem occurs in the software):

- Step-by-step description of how to replicate the problem:

- +

The device does not establish a connection / the software does not see my logger

The reasons why the connection between the data logger and the software is not established can be manifold. If you have several devices and none of them are connected, the problem could be due to the interface or the software configuration. If you have several devices and only one does not establish a connection, please refer to the instructions for your device. Check that the interface is correctly connected to the PC and that the logger is inserted correctly. Make sure that the parts that touch each other are dry and clean. Try disconnecting and reconnecting the interface after waiting a few seconds. You can also check that the USB drivers are installed correctly: To do this, open the Device Manager in the Windows Control Panel (access to this depends on both your version of Windows and the display mode you have set; in Windows 7 and 10, you can click Start and type "Device Manager" to find it). Check whether your interface is listed under "Ports (COM and LPT)" or under "USB Controller" (depending on the interface) without a note or warning symbol. If there are signs of problems, right-click on the interface and click on Update drivers. Select the option to search for drivers on your computer and open the folder where the drivers are located (in the Driver folder in the file downloaded with the software or in the installation folder of the software itself). You can also consult the following FAQs: SPD Software - Connection is not established TS Manager Software - The logger does not establish a connection High temperature data logger - The logger does not establish a connection

- +

- +

- +

- +

Navigation

Produkte

Branchen & Anwendungen